News

-

The Ultimate Guide to Choosing the Perfect Spiral Flute Tap Set

When it comes to threading holes, having the right tools is essential. One such tool that every professional or hobbyist needs in their arsenal is a quality spiral flute tap set. Whether you’re working on a woodworking project, automotive repair, or any other task that requires precise thre...Read more -

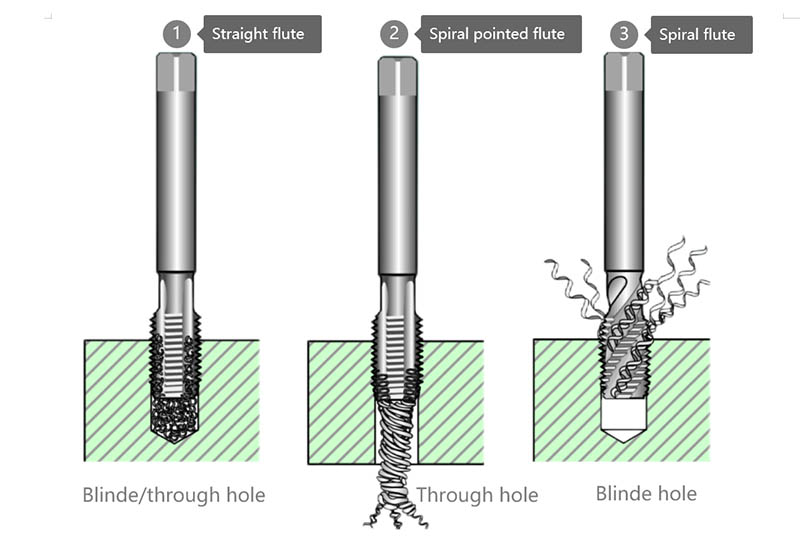

How to choose a tap for processing through and blind holes?

When we tapping threads, there are many types of taps for you to choose from? How do we choose a tool that suits us? Such as tapping hardened steel, tapping cast iron, or tapping aluminum, how should we do? We can choose threading taps based on the following tips 1. The ...Read more -

What reason caused taps break?

Every operator hates to break the tap. Removing a tap without damaging the parts is a painful task. In addition, tapping processing belongs to precision machining and is usually the final process of processing. This means that the breakage rate of the tap may determine t...Read more -

How to choose a tapping tools material and coating?

When we tapping threads, there are many types of taps for you to choose from. How can we choose them? Such as tapping hardened steel, tapping cast iron, or tapping aluminum, how should we do? 1. High-speed steel: Currently widely used as tap material, such as M2 (W6Mo5Cr4V2, 6542), M3, etc., we ...Read more -

How to choose a tapping tools threading tools?

When we tapping threads, there are many types of taps for you to choose from. How can we choose them? Such as tapping hardened steel, tapping cast iron, or tapping aluminum, how should we do? Yes, they are all used for tapping threads, but choosing a suitable tap require...Read more -

How to tapping Machining on hardened steel

When it comes to machining high hardness steel, finding the right tools can be a game-changer. Carbide taps for hardened steel, designed specifically for materials with a hardness range of HRC55-63, prove to be an essential asset in achieving precise and efficient metal...Read more -

Maximizing Aluminum Machining Efficiency with Spiral Carbide Taps

Introduction: Aluminum is a widely used material in various industries due to its lightweight, high strength, and excellent corrosion resistance. However, machining aluminum can pose challenges, such as the generation of long chips that can damage the workpiece and hinder the production process. ...Read more -

Enhancing Efficiency and Precision with Carbide Taps for Machining Cast Iron

In the world of machining, cast iron engine cylinder heads pose a unique challenge due to their hardness and abrasive nature. To overcome this, engineers and manufacturers have turned to carbide taps. These specialized tools have revolutionized the process of machining cast iron, providing increa...Read more -

How to choose the right tap for processing

When it comes to tapping threads, selecting the correct tap is critical to achieving satisfactory results. Various factors need to be considered, such as the type of thread, the material and hardness of the workpiece, the accuracy required, and even the shape standard of...Read more