Ceramic Capillary Bonding Capillary For semiconductor packaging

Product application

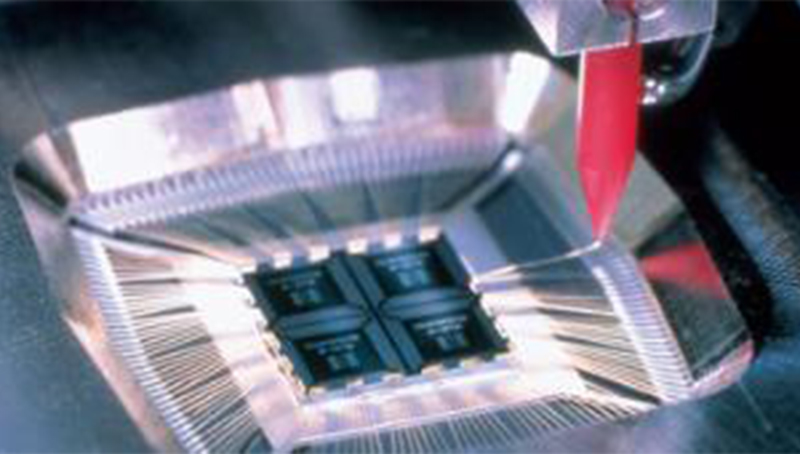

Ceramic Capillary is an axisymmetric ceramic tool with holes in the vertical direction, which belongs to an accurate micro structure ceramic component. In terms of application, the Ceramic Capillary is used as a wire bonding tool in the wire bonding process. WireBonding can make the metal lead closely weld with the substrate pad by using thin metal wires (copper, gold, etc.) and heat, pressure, and ultrasonic energy, so as to realize the electrical interconnection between chips and substrates and the information exchange between chips. Suitable for bonding and packaging of SCR, SAW, LED, diode, triode, IC chip and other circuits.

Product advantages

OPT Cutting Tools Co., LTD. is located in Shenzhen, Guangdong, China. It is a company integrating production, sales, research and development. And can undertake the design and manufacture of drawings, materials and non-standard tools. Firmly adopt domestic first-line production materials to ensure the stability of different batches of materials. Strictly control the production process to ensure the quality of tools. The company has considerable technical force, strong production capacity, scientific management, with the purpose of "survival by quality, development by reputation", and constantly forge ahead to provide customers with better products.

Accurate delivery, good service

1. OPT Cutting Tools has its own complete production, manufacturing and transportation system. On time delivery.

2. One to one communication and exchange can be carried out with customers to better provide customers with more suitable and better Ceramic bonding tools

3. Customize special parameters according to customer's special requirements;

Bonding Capillary Material upgrade

On the basis of the original aluminum oxide, zirconia, chromium oxide, etc. are added to make the molecular structure of the Ceramic Capillary more compact, with higher hardness, better wear resistance and longer service life. Reduce the wear and replacement times of ceramic cleaver tip during wire welding.

High precision, high dimensional precision, less machining and smooth surface.

The product has high precision, high dimensional precision, less machining amount and smooth surface.

The structure of the Ceramic Capillary is very precise and complex, and its key dimensions have a great impact on the wire bonding effect. OPT Cutting Tools strictly controls the production process to ensure the quality of tools. To achieve high product accuracy, high dimensional accuracy, less machining, and smooth surface. Our company is committed to the R&D and production of medium and high grade domestic ceramic bonding tools in the field of IC packaging. Ceramic powder and embryo parts are completely developed and produced independently.

![]()

BPP:150μm(μm/mil)

|

Part NO. |

WD |

H |

T |

CD |

OR |

α |

Θ |

CA |

|

A-1 |

38/1.5 |

51/2.0 |

229/9.0 |

102/4.0 |

38/1.5 |

8° |

30° |

120° |

|

A-2 |

38/1.5 |

51/2.0 |

152/6.0 |

66/2.6 |

10/0.4 |

0° |

30° |

90° |

|

A-3 |

38/1.5 |

51/2.0 |

229/9.0 |

86/3.4 |

102/4.0 |

0° |

30° |

90° |

|

A-4 |

38/1.5 |

51/2.0 |

203/8.0 |

86/3.4 |

61/2.4 |

0° |

30° |

90′ |

|

A-5 |

38/1.5 |

56/2.2 |

239/9.4 |

102/4.0 |

38/1.5 |

8° |

30° |

120° |

|

A-6 |

38/1.5 |

56/2.2 |

229/9.0 |

96/3.8 |

102/4.0 |

0° |

30° |

90° |

|

A-7 |

38/1.5 |

56/2.2 |

203/8.0 |

86/3.4 |

61/2.4 |

0° |

30° |

90° |

|

A-8 |

38/1.5 |

64/2.5 |

239/9.4 |

102/4.0 |

38/1.5 |

6° |

30° |

120° |

|

A-9 |

38/1.5 |

64/2.5 |

203/8.0 |

89/3.5 |

61/2.4 |

0° |

30° |

90° |

|

A-10 |

51/2.0 |

64/2.5 |

191/7.5 |

81/3.2 |

B/0.3 |

0° |

30° |

90° |

|

A-11 |

51/2.0 |

64/2.5 |

292/11.5 |

102/4.0 |

127/5.0 |

0° |

30° |

90° |

|

A-12 |

51/2.0 |

76/3.0 |

356/14.0 |

122/4.8 |

152/6.0 |

0° |

30° |

90° |

|

A-13 |

51/2.0 |

89/3.5 |

419/16.5 |

135/5.3 |

178/7.0 |

0° |

30° |

90° |

|

A-14 |

51.64/2.0.2.5 |

76/3.0 |

330/13.0 |

140/5.5 |

64/2.5 |

8° |

30° |

120° |

|

A-15 |

64.76/2.5.3.0 |

89/3.5 |

330/13.0 |

127/5.0 |

64/2.5 |

8° |

30° |

120° |

|

A-16 |

64.76/2.5.3.0 |

102/4.0 |

330/13.0 |

140/5.5 |

64/2.5 |

8° |

30° |

120° |

|

A-17 |

76/3.0 |

102/4.0 |

483/19.0 |

168/6.6 |

203/8.0 |

0° |

30° |

90° |

BPP:140μm(μm/mil)

|

Part NO. |

WD |

H |

T |

CD |

OR |

α |

Θ |

CA |

|

B-1 |

22/0.9 |

33/1.3 |

140/5.5 |

64/2.5 |

20/0.8 |

8° |

30° |

120° |

|

B-2 |

25/1.0 |

38/1.5 |

165/6.5 |

74/2.9 |

25/1.0 |

8° |

30° |

120° |

|

B-3 |

25/1.0 |

38/1.5 |

89/3.5 |

53/2.1 |

B/0.3 |

0° |

30° |

90° |

|

B-4 |

25/1.0 |

38/1.5 |

114/4.5 |

53/2.1 |

8/0.3 |

0° |

30° |

90° |

|

B-5 |

25/1.0 |

38/1.5 |

178/7.0 |

64/2.5 |

76/3.0 |

0° |

30° |

90° |

|

B-6 |

25/1.0 |

38/1.5 |

203/8.0 |

53/2.1 |

89/3.5 |

0° |

30° |

90° |

|

B-7 |

25/1.0 |

43/1.7 |

165/6.5 |

74/2.9 |

25/1.0 |

8° |

30° |

120° |

|

B-8 |

25/1.0 |

43/1.7 |

203/8.0 |

53/2.1 |

89/3.5 |

0° |

30° |

90° |

|

B-9 |

25.30/1.0.1.2 |

43/1.7 |

229/9.0 |

74/2.9 |

30/1.2 |

8° |

30° |

120° |

|

B-10 |

25.30/1.0.1.2 |

43/1.7 |

152/6.0 |

59/2.3 |

B/0.3 |

8° |

30° |

120° |

|

B-11 |

25.30/1.0.1.2 |

43/1.7 |

203/8.0 |

74/2.9 |

89/3.5 |

0° |

30° |

90° |

|

B-12 |

25.30/1.0.1.2 |

46/1.8 |

229/9.0 |

74/2.9 |

38/1.5 |

8° |

30° |

120° |

|

B-13 |

30/1.2 |

46/1.8 |

203/8.0 |

76/3.0 |

89/3.5 |

0° |

30° |

90° |

BPP:100μm(μm/mil)

|

Part NO. |

WD |

H |

T |

CD |

OR |

α |

Θ |

CA |

|

C-1 |

25/1.0 |

38/1.5 |

130/5.1 |

53/2.1 |

30/1.2 |

11 |

30° |

90° |

|

C-2 |

30/1.2 |

38/1.5 |

130/5.1 |

56/2.2 |

30/1.2 |

11 |

30° |

90° |

|

C-3 |

30/1.2 |

38/1.5 |

130/5.1 |

56/2.2 |

30/1.2 |

8′ |

30° |

90° |

|

C-4 |

30/1.2 |

38/1.5 |

130/5.1 |

56/2.2 |

30/1.2 |

4′ |

30° |

90° |

|

C-5 |

30/1.2 |

41/1.6 |

130/5.1 |

59/2.3 |

30/1.2 |

11 |

30° |

90° |

BPP:90μm(μm/mil)

|

Part NO. |

WD |

H |

T |

CD |

OR |

α |

Θ |

CA |

|

D-1 |

25/1.0 |

33/1.3 |

109/4.3 |

51/2.0 |

13/0.5 |

11° |

30° |

90° |

|

D-2 |

25/1.0 |

33/1.3 |

109/4.3 |

51/2.0 |

13/0.5 |

8° |

30° |

90° |

|

D-3 |

25/1.0 |

33/1.3 |

109/4.3 |

51/2.0 |

13/0.5 |

4° |

30° |

90° |

|

D-4 |

25/1.0 |

35/1.4 |

109/4.3 |

51/2.0 |

20/0.8 |

11° |

30° |

90° |

|

D-5 |

30/1.2 |

38/1.5 |

109/4.3 |

51/2.0 |

20/0.8 |

11° |

30° |

90° |

|

D-6 |

30/1.2 |

38/1.5 |

109/4.3 |

53/2.1 |

1310.5 |

8° |

30° |

90° |

|

D-7 |

30/1.2 |

38/1.5 |

109/4.3 |

53/2.1 |

13/0.5 |

4° |

30° |

90° |

BPP:80μm(μm/mil)

|

Part NO. |

WD |

H |

T |

CD |

OR |

α |

Θ |

CA |

|

E-1 |

25/1.0 |

33/1.3 |

99/3.9 |

48/1.9 |

13/0.5 |

4° |

30° |

90° |

|

E-2 |

25/1.0 |

33/1.3 |

99/3.9 |

4B/1.9 |

13/0.5 |

8° |

30° |

90° |

|

E-3 |

25/1.0 |

33/1.3 |

99/3.9 |

48/1.9 |

13/0.5 |

11° |

30° |

90° |

|

E-4 |

25/1.0 |

35/1.4 |

99/3.9 |

46/1.8 |

13/0.5 |

11° |

30° |

90° |

|

E-5 |

30/1.2 |

38/1.5 |

99/3.9 |

51/2.0 |

13/0.5 |

4° |

30° |

90° |

|

E-6 |

30/1.2 |

3B/1.5 |

99/3.9 |

51/2.0 |

13/0.5 |

8° |

30° |

90° |

BPP:70μm(μm/mil)

|

Part NO. |

WD |

H |

T |

CD |

OR |

α |

Φ |

CA |

|

F-1 |

25/1.0 |

30/1.2 |

91/3.6 |

43/1.7 |

10/0.4 |

8° |

30° |

90° |

|

F-2 |

25/1.0 |

30/1.2 |

91/3.6 |

43/1.7 |

10/0.4 |

4° |

30′ |

90° |

|

F-3 |

25/1.0 |

33/1.3 |

91/3.6 |

43/1.7 |

13/0.5 |

11° |

30′ |

90° |

BPP:60μm(μm/mil)

|

Part NO. |

WD |

H |

T |

CD |

OR |

α |

Φ |

CA |

|

G-1 |

23/0.9 |

28/1.1 |

81/3.2 |

35/1.4 |

13/0.5 |

11° |

30° |

90° |

|

G-2 |

25/1.0 |

30/1.2 |

81/3.2 |

35/1.4 |

13/0.5 |

11° |

30° |

90° |