Carbide tap for hardened steel

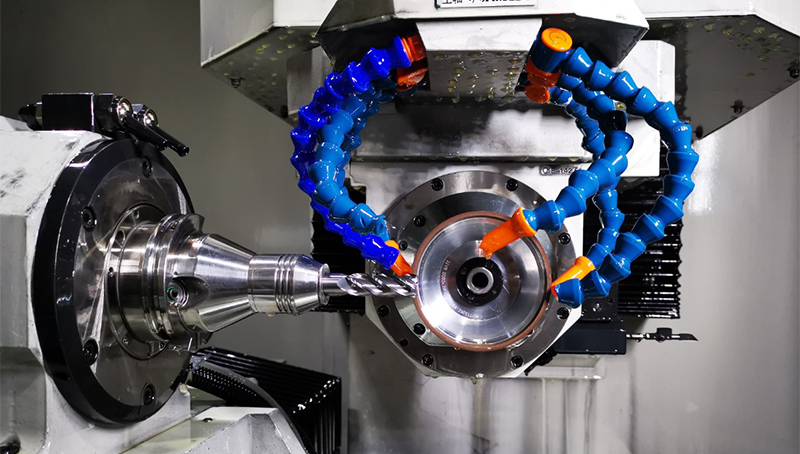

Product application

Teeth are used in all industries of connection pieces, all kinds of materials to tap teeth! For example, automobile engine, aircraft manufacturing, home appliances manufacturing, mobile phone manufacturing, etc., all need to attack teeth! How to choose a good tap supplier, very important!

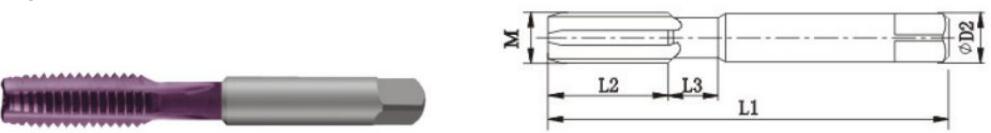

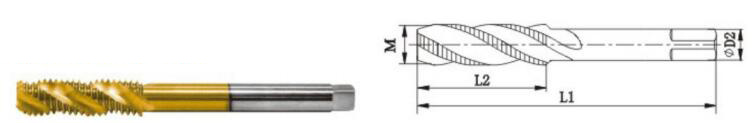

When you have special requirements, such as the bottom need to avoid the hole, or the bottom need to drill, we can according to your production conditions, increase the hole on the tap, or increase the cutting edge of drilling and milling, in order to meet the different needs of different customers!

There are many kinds of tap, the shape of the shank and the requirements of the tap and the material requirements are different, please pay attention to the order, also can find our customer service staff, ask for more detailed information.

Taps with reinforced shank 4035

|

Size |

Pitch |

Flute |

O.A.L |

Thread lenath |

Shank Dia. |

Model No. |

|

|

M |

P |

Z |

L1 |

L2 |

D2 |

Uncoated |

Coated |

|

M3 |

0.50 |

3 |

48 |

11 |

2.24 |

4135-030A |

■4135T-030A |

|

M3.5 |

0.60 |

3 |

50 |

13 |

2.50 |

4135-035B |

■4135T-035B |

|

M4 |

0.70 |

3 |

53 |

13 |

3.15 |

4135-040C |

■4135T-040C |

|

M4X0.5 |

0.50 |

3 |

53 |

13 |

3.15 |

4135-040A |

■4135T-040A |

|

M4.5 |

0.75 |

3 |

53 |

13 |

3.55 |

4135-045D |

■4135T-045D |

|

M4.5X0.5 |

0.50 |

3 |

53 |

13 |

3.55 |

4135-045A |

■4135T-045A |

|

M5 |

0.80 |

3 |

58 |

16 |

4.00 |

4135-050E |

■4135T-050E |

|

M5X0.5 |

0.50 |

3 |

58 |

16 |

4.00 |

4135-050A |

■4135T-050A |

|

M5.5X0.5 |

0.50 |

3 |

62 |

17 |

4.00 |

4135-055A |

■4135T-055A |

|

M6 |

1.00 |

3 |

66 |

19 |

4.50 |

4135-060F |

■4135T-060F |

|

M6X0.75 |

0.75 |

3 |

66 |

19 |

4.50 |

4135-060D |

■4135T-060D |

|

M7 |

1.00 |

4 |

66 |

19 |

5.60 |

4135-070F |

■4135T-070F |

|

M7X0.75 |

0.75 |

4 |

66 |

19 |

5.60 |

4135-070D |

■4135T-070D |

|

M8 |

1.25 |

4 |

72 |

22 |

6.30 |

4135-080G |

■4135T-080G |

|

M8X0.75 |

0.75 |

4 |

66 |

19 |

6.30 |

4135-080D |

■4135T-080D |

|

M8X1 |

1.00 |

4 |

72 |

22 |

6.30 |

4135-080F |

■4135T-08OF |

|

M9 |

1.25 |

4 |

72 |

22 |

7.10 |

4135-090G |

■4135T-090G |

|

M9X0.75 |

0.75 |

4 |

66 |

19 |

7.10 |

4135-090D |

■43509D |

|

M9X1 |

1.00 |

4 |

72 |

22 |

7.10 |

4135-090F |

■4135T-090F |

|

M10 |

1.50 |

4 |

80 |

24 |

8.00 |

4135-100H |

■4135T-100H |

|

M10X0.75 |

0.75 |

4 |

73 |

20 |

8.00 |

4135-100D |

■4135T-100D |

|

M10X1 |

1.00 |

4 |

80 |

24 |

8.00 |

4135-100F |

■4135T-100F |

|

M10X1.25 |

1.25 |

4 |

80 |

24 |

8.00 |

4135-100G |

■4135T-100G |

|

M11 |

1.50 |

4 |

85 |

25 |

8.00 |

4135-110H |

■4135T-110H |

machine tap with spiral flute 41B5

|

Size |

Pitch |

Flute |

O.A.L |

Thread lenath |

Shank Dia. |

Model No. |

|

|

M |

P |

Z |

L1 |

L2 |

D2 |

Uncoated |

Coated |

|

M3 |

0.60 |

3 |

60 |

11 |

3.15 |

41B5-030A |

41B5T-030A |

|

M3.5 |

0.60 |

3 |

60 |

13 |

3.65 |

41B5-035B |

■41B5T-036B |

|

M4 |

0.70 |

3 |

63 |

13 |

4.00 |

41B5-040C |

■41B5T-040C |

|

M4.5 |

0.75 |

3 |

53 |

13 |

4.60 |

41B5-045D |

■41B5T-045D |

|

M5 |

0.80 |

3 |

58 |

16 |

5.00 |

41B5-050E |

■41B5T-050E |

|

M5X0.5 |

0.60 |

3 |

68 |

16 |

5.00 |

41B5-050A |

■41B5T-050A |

|

M6 |

1.00 |

3 |

66 |

16 |

6.30 |

41B5-060F |

■41B5T-060F |

|

M6X0.75 |

0.75 |

3 |

66 |

19 |

6.30 |

41B5-060D |

■41B5T-060D |

|

M7 |

1.00 |

3 |

66 |

19 |

5.60 |

41B5-070F |

■41B5T-070F |

|

M7X0.75 |

0.75 |

3 |

66 |

19 |

5.60 |

41B5-070D |

■41B5T-070D |

|

M8 |

1.25 |

3 |

72 |

22 |

6.30 |

41B5-080G |

■41B5T-080G |

|

M8X1 |

1.00 |

3 |

69 |

19 |

6.30 |

41B5-080F |

■41B5T-080F |

|

M9 |

1.25 |

3 |

72 |

22 |

7.10 |

41B5-090G |

■41B5T-090G |

|

M9X1 |

1.00 |

3 |

69 |

19 |

7.10 |

41B5-090F |

■41B5T-090F |

|

M10 |

1.50 |

3 |

80 |

24 |

8.00 |

41B5-100H |

■41B5T-100H |

|

M10X1 |

1.00 |

3 |

80 |

20 |

8.00 |

41B5-100F |

■41B5T-100F |

|

M10X1.25 |

1.25 |

3 |

80 |

20 |

8.00 |

41B5-100G |

■41B5T-100G |