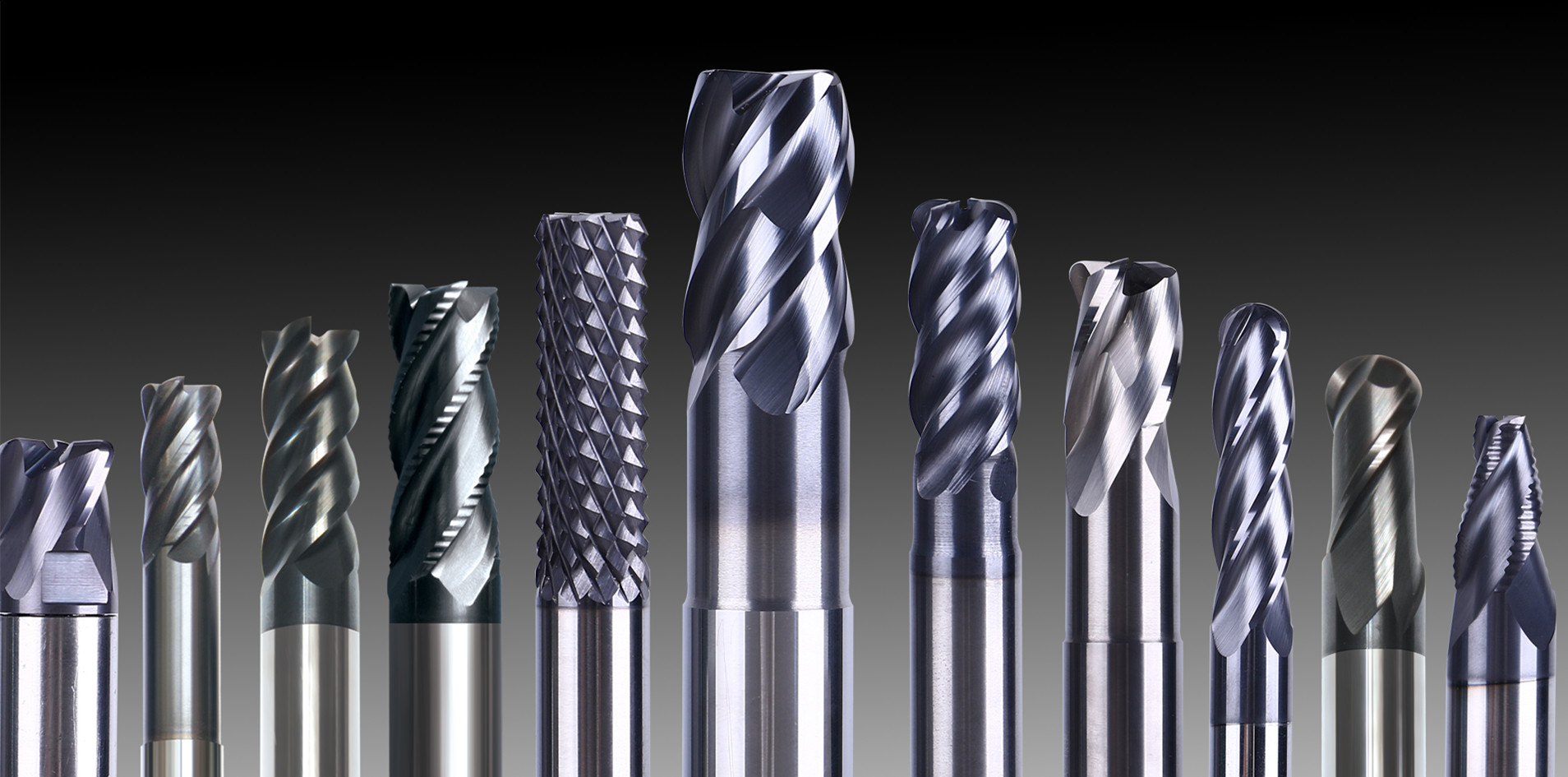

Solid carbide end mills for stainless steel

Product application

Excellent adhesion between coating and substrate ensures processing stability and prolongs tool life

Smooth coating surface reduces cutting resistance and improves tool wear resistance

Suitable for: Steel, stainless steel, aluminum, cast iron and high hard steel,Widely used in aerospace,chip packaging and other industries, automobile manufacturing, mobile phone manufacturing,

Product advantages

The coating used by OPT is 40% stronger than the ordinary coating .

New "nanostructure" coating technology is adopted, and the coating structure is compact.

Excellent adhesion between coating and substrate ensures processing stability and prolongs tool life.

Smooth coating surface reduces cutting resistance and improves tool wear resistance.

3123H General carbide end mills

|

Mill Dia. |

Shank Dia. |

O.A.L. |

Flute length |

Flute No. |

Model No. |

|

|

D1(h9) |

D2(h6) |

L1 |

L2 |

Z |

Uncoated |

Coated |

|

3 |

4 |

57 |

7 |

2 |

3123H-030 |

■ 3123H-030T |

|

4 |

4 |

57 |

8 |

2 |

3123H-040 |

■ 3123H-040T |

|

5 |

6 |

57 |

10 |

2 |

3123H-050 |

■ 3123H-050T |

|

6 |

6 |

57 |

10 |

2 |

3123H-060 |

■ 3123H-060T |

|

7 |

8 |

63 |

13 |

2 |

3123H-070 |

■ 3123H-070T |

|

8 |

8 |

63 |

16 |

2 |

3123H-080 |

■ 3123H-080T |

|

9 |

10 |

72 |

16 |

2 |

3123H-090 |

■ 3123H-090T |

|

10 |

10 |

72 |

19 |

2 |

3123H-100 |

■ 3123H・100T |

|

12 |

12 |

83 |

22 |

2 |

3123H-120 |

■ 3123H-120T |

|

14 |

14 |

83 |

22 |

2 |

3123H・140 |

■ 3123H・140T |

|

16 |

16 |

92 |

26 |

2 |

3123H-160 |

■ 3123H-160T |

|

18 |

18 |

92 |

26 |

2 |

3123H-180 |

■ 3123H-180T |

|

20 |

20 |

104 |

32 |

2 |

3123H-200 |

■ 3123H-200T |

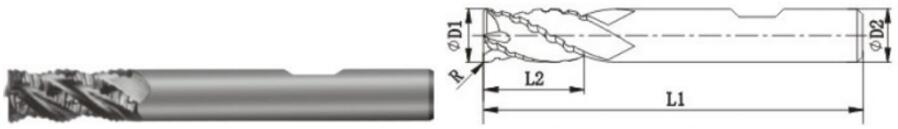

3941L Four-blade rear wave cutter

|

Mill Dia. |

Shank Dia. |

O.A.L. |

Flute length. |

R Dia. |

Flute No. |

Model No. |

|

|

D1(h9) |

D2(h6) |

L1 |

12 |

R |

z |

Uncoated |

Coated |

|

8 |

8 |

63 |

19 |

1 |

4 |

3941L-080 |

■ 3941L-080T |

|

10 |

10 |

72 |

22 |

1 |

4 |

3941L-100 |

■ 3941L-100T |

|

12 |

12 |

83 |

26 |

1 |

4 |

3941L-120 |

■ 3941L-120T |

|

14 |

14 |

83 |

26 |

1 |

4 |

3941L-140 |

■ 3941L-140T |

|

16 |

16 |

92 |

32 |

1 |

4 |

3941L-160 |

■ 3941L-160T |

|

18 |

18 |

92 |

32 |

1 |

4 |

3941L-180 |

■ 3941L-180T |

|

20 |

20 |

104 |

38 |

1 |

4 |

3941L-200 |

■ 3941L-200T |