News

-

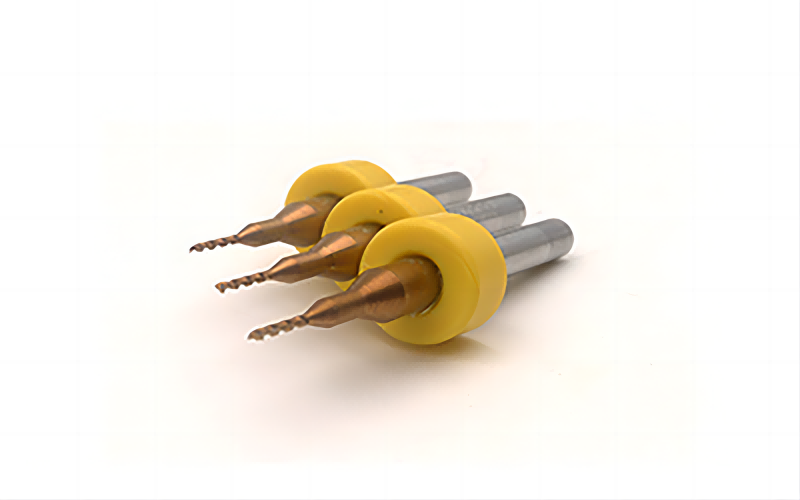

Threading tools for all your needs

Threading tools such as taps and dies play a vital role in various industries that require precise threading of their products. From manufacturing automotive parts to complex components for the aerospace industry, having the right threading cutter is critical to obtaining accurate and efficient r...Read more -

How to choose the right cast iron thread tap

Introduce: Machining cast iron materials requires precision and the right tool to achieve the best results. One tool that plays an important role in this process is the thread tap. In this blog, we will discuss two types of thread taps, thread taps for machining cast iron materials and straight f...Read more -

Advantages of machining with internal coolant

Deep hole machining requires specialized tools that can effectively cool and remove chips while maintaining accuracy and efficiency. One such tool is an internally cooled dril designed with materials such as tungsten carbide, carbide and rhenium. These drills are specially manufactured for deep h...Read more -

Manufacturing process of twist drill

According to different processing methods, the twist drills currently on the market are roughly divided into the following types: 1. Rolled twist drill After the high-speed steel is heated and burned red, the shape of the twist drill is quickly rolled out at one time. Afterwards, the twist drill ...Read more -

Precautions for twist drill sharpening

1.The sharpening drill generally adopts a grinding wheel with a particle size of 46~80 mesh, and the hardness is medium-soft grade aluminum oxide grinding wheel. To grind the outer corner of the grinding wheel to a smaller fillet radius, if the fillet radius is too large, the main cutting edge wi...Read more -

How to sharpen the twist drill sharp and durable?

The vertex angle of the twist drill is generally 118°, but it can also be regarded as 120°. There is generally no problem if you can master the following 6 skills for sharpening drills. 1.Before grinding the drill bit, the main cutting edge of the drill bit and the grinding wheel surface should b...Read more -

What can a twist drill drill?

The use of twist drills is directly related to the style and type. On the market, there are cobalt-containing stainless steel twist drills, parabolic deep-hole twist drills, gold-containing twist drills, titanium-plated twist drills, high-speed steel twist drills, and extra-long twist drills. The...Read more -

The functions and characteristics of commonly used thread milling tools

With the popularization of CNC machine tools, the application of thread milling technology in the mechanical manufacturing industry is increasing. Thread milling is to form thread by three-axis linkage of CNC machine tool and spiral interpolation milling with thread milling cutter. Each Circular ...Read more -

Advantages of tungsten steel milling cutters

Analysis of the advantages of tungsten steel milling cutters to improve processing quality and efficiency! Tungsten steel milling cutter is a commonly used machining tool with many advantages, which can greatly improve machining quality and efficiency. Let’s carefully analyze it below. Fir...Read more