End mills process stainless steel and heat-resistant alloys-T504

End mills process stainless steel and heat-resistant alloys-M101

|

Designation |

D |

d |

H |

L |

Z |

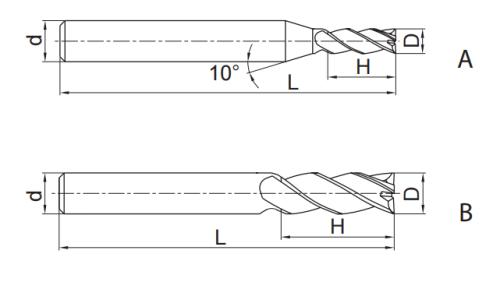

Fig. |

|

VSE-ZL-D3.0 |

3.0 |

6 |

12 |

75 |

2/4 |

A |

|

VSE-ZL-D4 |

4 |

6 |

15 |

75 |

2/4 |

A |

|

VSE-ZL-D5 |

5 |

6 |

20 |

75 |

2/4 |

A |

|

VSE-ZL-D6 |

6 |

6 |

20 |

75 |

2/4/6 |

B |

|

VSE-ZL-D8 |

8 |

8 |

25 |

100 |

2/4/6 |

B |

|

VSE-ZL-D10 |

10 |

10 |

30 |

100 |

2/4/6 |

B |

|

VSE-ZL-D12 |

12 |

12 |

35 |

100 |

2/4/6 |

B |

|

VSE-ZL-D16 |

16 |

16 |

50 |

150 |

2/4/6 |

B |

|

VSE-ZL-D20 |

20 |

20 |

55 |

150 |

2/4/6 |

B |

|

Designation |

D |

d |

H |

L |

Z |

Fig. |

|

VSE-Z-D3.0S |

3.0 |

4 |

8 |

50 |

2/4 |

A |

|

VSE-Z-D4.0S |

4.0 |

4 |

11 |

50 |

2/4 |

B |

|

VSE-Z-D3.0 |

3.0 |

6 |

8 |

50 |

2/4 |

A |

|

VSE-Z-D4.0 |

4.0 |

6 |

11 |

50 |

2/4 |

A |

|

VSE-Z-D5.0 |

5.0 |

6 |

13 |

50 |

2/4 |

A |

|

VSE-Z-D6.0 |

6.0 |

6 |

16 |

50 |

2/4/6 |

B |

|

VSE-Z-D8.0 |

8.0 |

8 |

20 |

60 |

2/4/6 |

B |

|

VSE-Z-D10 |

10.0 |

10 |

25 |

75 |

2/4/6 |

B |

|

VSE-Z-D12 |

12.0 |

12 |

30 |

75 |

2/4/6 |

B |

|

VSE-Z-D16 |

16.0 |

16 |

45 |

100 |

2/4/6 |

B |

|

VSE-Z-D18 |

18.0 |

18 |

45 |

100 |

2/4/6 |

B |

|

VSE-Z-D20 |

20.0 |

20 |

45 |

100 |

2/4/6 |

B |

Write your message here and send it to us