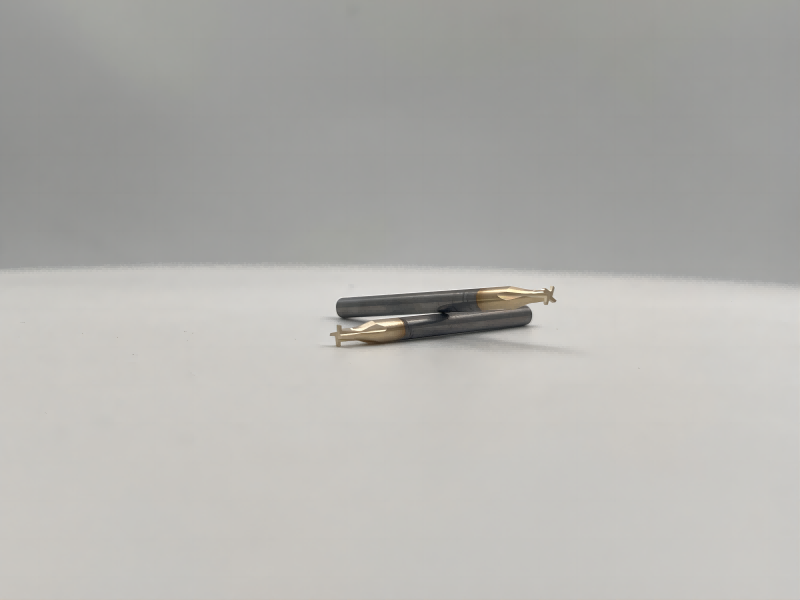

T-Slot Milling Cutter is a professional production and processing of T-shaped hard milling cutters for various mechanical equipment countertops or other structures. Apart from specifications and models, there are not many classifications of T-shaped slot milling cutters. From a structural perspective, they can be divided into straight shank slot milling cutters and conical shank slot milling cutters. From a material perspective, they can be divided into embedded carbide T-slot milling cutters and full carbide T-slot milling cutters.

The first choice is very simple, which is to choose whether to use a straight handle or a T-shape based on one’s own model or the size of a special tool.

Embedded carbide T-slot milling cutter, Although it is carbide, it refers to the small blade embedded at the top of the T-shaped blade, in other words, the blade at the top of the head is carbide,The collet and other parts are all made of spring steel material, and this type of design scheme fully utilizes the characteristic of using only the cutting edge for the foundation of the cutting tool. Therefore, using carbide embedding in the cutting edge part can reasonably save a lot of costs, and in addition, it does not harm the normal function of the milling cutter, which is a very useful way.

So some people may think, then everyone wouldn’t choose a full carbide milling cutter. Actually, existence is reasonable, Although the T-shaped milling cutter embedded in carbides has significant advantages in terms of price, compared to full carbides, it has a significant disadvantage, which is the difficulty of precision. As a part of the blade is embedded, various deviations are inevitable. Therefore, if the precision specified for the T-shaped groove of your product workpiece or mechanical equipment is very high, it is necessary to choose a full carbide T-shaped milling cutter.

I believe you have already figured out the situation for selecting a T-shaped iron cutter. It is actually very simple to use. When producing and processing high-precision product workpieces, be sure to choose a T-shaped groove milling cutter to meet the processing requirements. Generally, for product workpieces with low precision requirements, a T-shaped groove milling cutter can be appropriately selected.

Post time: Jun-26-2023