GFRP glass fiber reinforced plastic, also known as fiber reinforced plastic, generally refers to a reinforced plastic made of unsaturated polyester, epoxy resin, and phenolic resin matrix reinforced with glass fiber, and reinforced with glass fiber or its products, known as glass fiber reinforced plastic. Nearly 70% of the production of fiberglass is used to manufacture fiberglass. The hardness of fiberglass is much lighter than that of steel, and the PCD turning tool and milling cutter are the best choice for fiberglass in turning and milling processes!

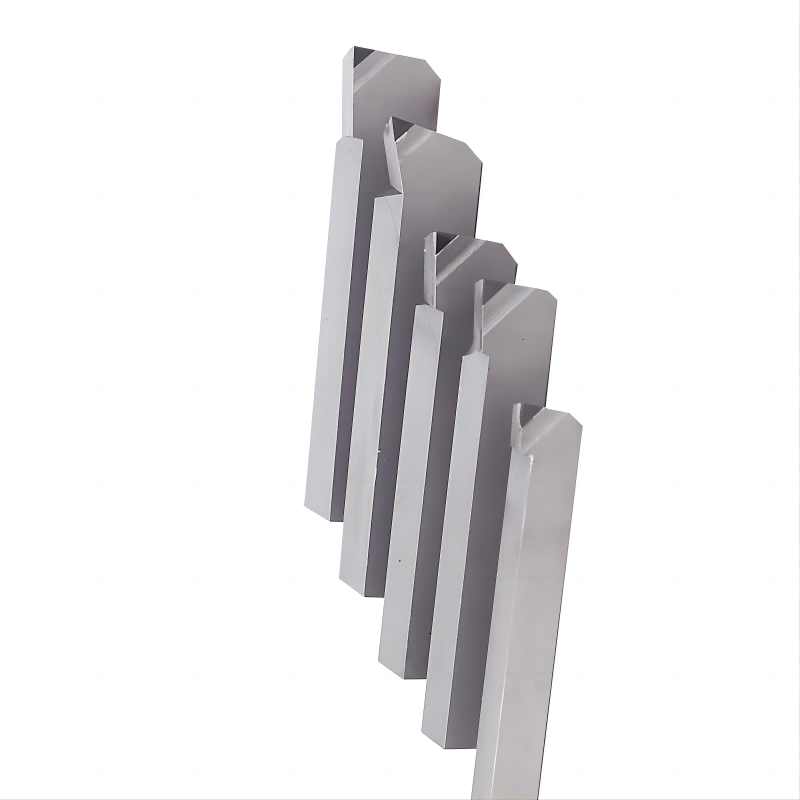

PCD turning tool

The commonly used tool in the cutting process of fiberglass is turning. The CDW302 polycrystalline Diamond Blade is often used for turning fiberglass. The CDW302 material blade not only greatly improves the cutting speed of turning fiberglass, but also enhances its durability by several tens of times compared to hard alloys. Due to the fact that fiberglass is mostly a brittle material, its elastic modulus is small and its elastic recovery is large. To improve heat dissipation conditions, CDW302 material cutting tools increase the cutting ability of the cutting edge, making cutting light and fast.

When turning fiberglass, the CDW302 brand PCD turning tool has high durability, high turning smoothness, and high processing efficiency. Generally, CDW302Diamond turning tool is used for dry cutting without adding cutting fluid. If the cutting temperature is too high due to high rotational speed or poor thermal conductivity of the workpiece, water-based cutting fluid can be used for cooling.

PCD milling cutter

Diamond milling cutter is divided into two types:PCD end milling cutter and Diamond coated milling cutter

1. Diamond coated milling cutter is a process of coating a layer of diamond film on the surface of a hard alloy substrate, which increases the hardness and tool life on the basis of the high toughness of the hard alloy. However, due to the thin coating thickness, after long-term milling, the hard alloy substrate will be exposed, resulting in accelerated wear. Diamond coated milling cutters are mainly used for small diameter milling cutters.

2. PCD end milling cutter is a PCD (diamond) sheet welded on a hard alloy substrate, which uses a PCD blade to mill fiberglass. Its efficiency is dozens of times higher than that of a hard alloy milling cutter. This type of PCD milling cutter has a hardness of 9000HV and high wear resistance. At the same time, the cutting edge is sharp, which can effectively cut fibers, avoid fiber material layering and burrs, reduce auxiliary time such as grinding tools and polishing, reduce operator labor intensity, and greatly improve production efficiency. It is currently an ideal tool for milling fiberglass.

OPT cutting tools is a high-quality supplier of Diamond cutting tools.

OPT cutting tools is a high-quality supplier of Diamond cutting tools.

We support you in the procurement of your annual requirements at competitive prices, offering high quality and a comprehensive range of services.

Post time: Jun-02-2023