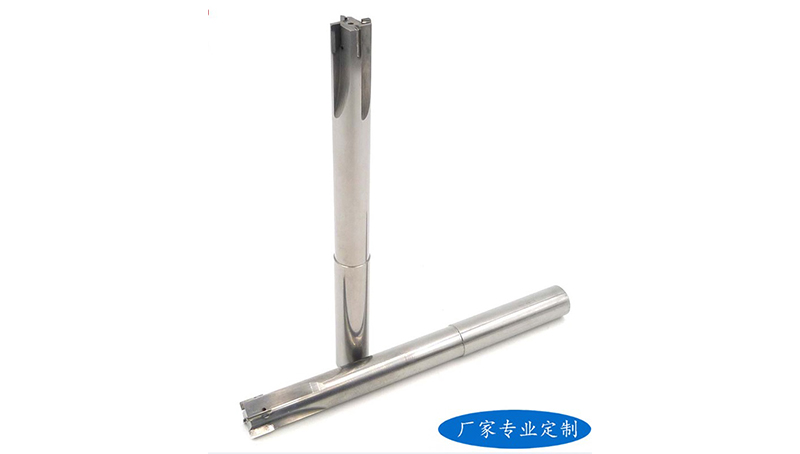

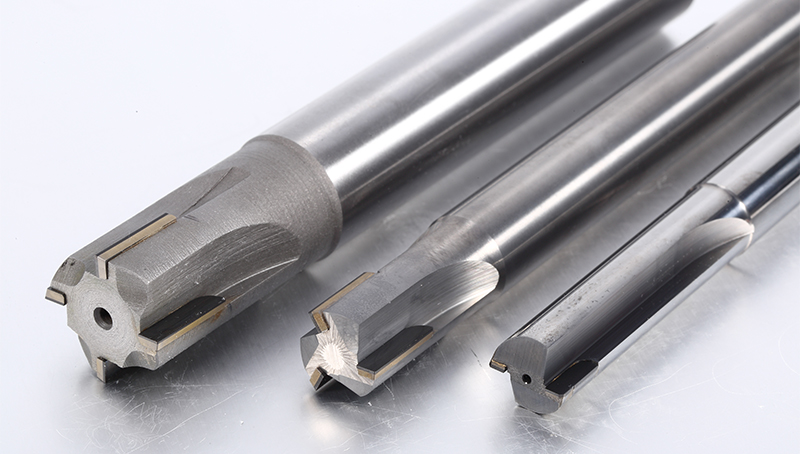

PCD ball nose end mill

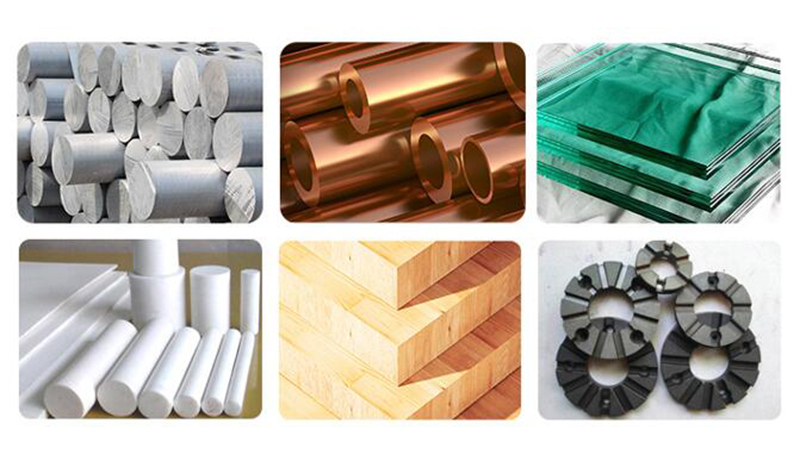

PCD milling cutter in aluminum alloy and non-ferrous metal or wood processing speed, high production capacity, good product quality, in aluminum alloy or carbon fiber materials, can better replace tungsten steel tools! Is the choice of modern machining to improve efficiency, pcd tool is both environmentally friendly and reliable.

PCD end mill-multi flutes

|

Model No |

Dimension. mm |

Material |

|||||

|

d1 |

d2 |

11 |

l2 |

13 |

r |

||

|

E0500060060LP2001 |

5 |

6 |

36 |

60 |

5 |

0.1 |

PCD |

|

E0500060060LP2002 |

5 |

6 |

36 |

60 |

5 |

0.2 |

PCD |

|

E0500060060LP2003 |

5 |

6 |

36 |

60 |

5 |

0.3 |

PCD |

|

E0600060060LP2001 |

6 |

6 |

36 |

60 |

5 |

0.1 |

PCD |

|

E0600060060LP2002 |

6 |

6 |

36 |

60 |

5 |

0.2 |

PCD |

|

E0600060060LP2003 |

6 |

6 |

36 |

60 |

5 |

0.3 |

PCD |

|

E0800080080LP2001 |

8 |

8 |

40 |

80 |

7 |

0.1 |

PCD |

|

E0800080080LP2002 |

8 |

8 |

40 |

80 |

7 |

0.2 |

PCD |

|

E0800080080LP2003 |

8 |

8 |

40 |

80 |

7 |

0.3 |

PCD |

|

E1000100080LP2001 |

10 |

10 |

40 |

80 |

7 |

0.1 |

PCD |

|

E1000100080LP2002 |

10 |

10 |

40 |

80 |

7 |

0.2 |

PCD |

|

E1000100080LP2003 |

10 |

10 |

40 |

80 |

7 |

0.3 |

PCD |

|

E1200120080LP4001 |

12 |

12 |

40 |

80 |

10 |

0.1 |

PCD |

|

E1200120080LP4002 |

12 |

12 |

40 |

80 |

10 |

0.2 |

PCD |

|

E1200120080LP4003 |

12 |

12 |

40 |

80 |

10 |

0.3 |

PCD |

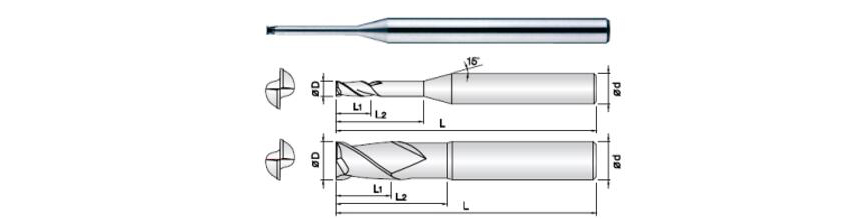

PCD CBN end mill

|

Order No. |

Size(mm) |

number of teeth Z |

||||

|

d |

D |

L1 |

L2 |

L |

||

|

CA-1E-D0.8 |

4 |

0.8 |

1.6 |

6 |

40 |

1 |

|

CA-1E-D0.9 |

4 |

0.8 |

1.8 |

6 |

40 |

1 |

|

CA-1E-D010 |

4 |

1 |

2 |

6 |

40 |

1 |

|

CA-1E-D012 |

4 |

1.2 |

2.5 |

7 |

40 |

1 |

|

CA-1E-D015 |

4 |

1.5 |

3 |

8 |

40 |

1 |

|

CA-1E-D020 |

4 |

2 |

4.2 |

9 |

40 |

1 |

|

CA-1E-D025 |

4 |

2.5 |

5 |

10 |

40 |

1 |

|

CA-1E-D030 |

4 |

3 |

5.5 |

12 |

40 |

1 |

|

CA-1E-D040 |

4 |

4 |

7 |

13 |

40 |

1 |

|

CA-2E-D060 |

6 |

6 |

8 |

15 |

50 |

2 |

|

CA-2EL-D060 |

6 |

6 |

10 |

15 |

75 |

2 |

|

CA-2E-D080 |

8 |

8 |

10 |

18 |

50 |

2 |

|

CA-2EL-D080 |

8 |

8 |

12 |

20 |

75 |

2 |

|

CA-2E-D100 |

10 |

10 |

12 |

25 |

60 |

2 |

|

CA-2EL-D100 |

10 |

10 |

15 |

30 |

100 |

2 |

|

CA-2E-D120 |

12 |

12 |

12 |

25 |

75 |

2 |

|

CA-2EL-D120 |

12 |

12 |

16 |

35 |

100 |

2 |