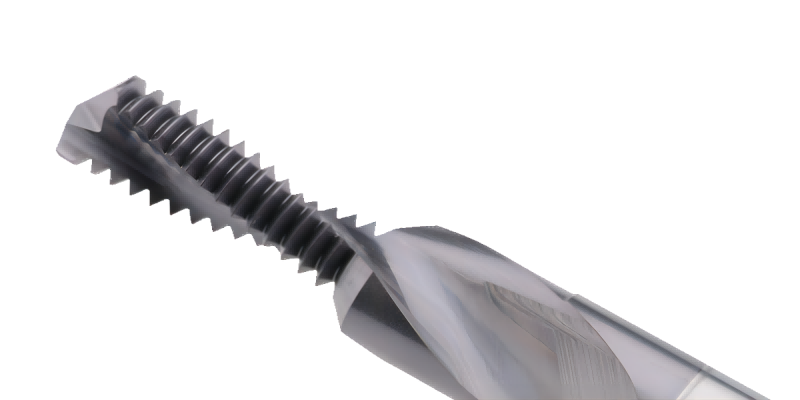

As a craftsman, have you ever encountered the problem of how to improve processing efficiency? If so, then thread milling is an indispensable tool for you! The use of thread milling tools and three-axis linkage of the machining center, namely X and Y axis arc interpolation, and Z-axis linear feed milling method, not only can quickly and efficiently process large hole threads and threaded holes of difficult to machine materials, but also has the following characteristics:

1、 The machining speed is fast, the efficiency is good, and the machining accuracy is decent. Small tools made of hard alloy materials have fast cutting speed and high manufacturing efficiency, which can ensure high thread accuracy and also reduce tool costs.

2、 The milling cutter has a wide range of applications, as long as the search distance is the same, whether it is a left swing pattern or a right swing pattern, it can use a single tool, which is very practical.

https://www.optcuttingtools.com/three-in-one-drilling-taps-for-hardened-steel-solid-carbide-taps-spiral-pointed-tap-product/

3、 Milling is easy to remove chips and cool, and the cutting condition is good. Compared to screw taps, they are particularly suitable for thread processing of difficult to machine materials such as aluminum, copper, and stainless steel, ensuring the quality of thread processing and the safety of the workpiece.

4、 Suitable for processing blind holes with short threaded bottom holes and holes without undercuts, as there is no tool front end guidance.

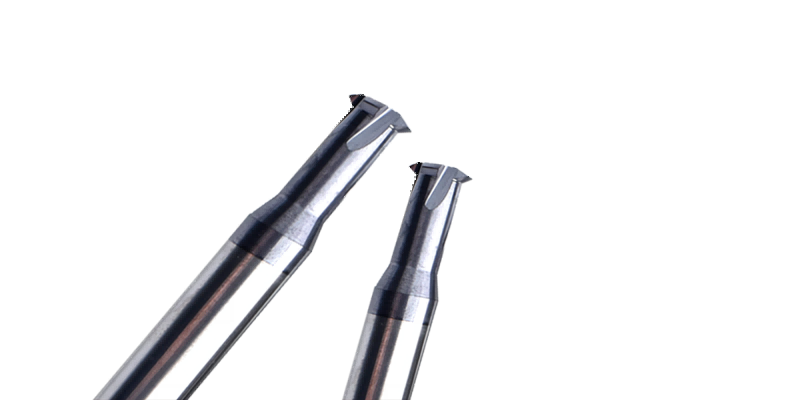

In addition, thread milling tools can also be classified according to different processing needs, among which machine clamp type hard alloy blade milling cutters and integral hard alloy milling cutters are two common types. Machine clamp type tools have a wide range of applications, which can process holes with thread depth less than the length of the blade or holes with thread depth greater than the length of the blade, Integral hard alloy milling cutters are generally used for machining holes with thread depths less than the tool length.

Post time: Jul-22-2023