Tool is one of the important parts in machining machine tools. With the development of science and technology, the tool has changed from the original alloy tool to the most commonly used coated tool. The regrinding and re-coating of cemented carbide and high-speed steel tools are common processes at present. Although the price of tool regrinding or recoating is only a small part of the manufacturing cost of new tools, it can prolong the tool life and reduce the manufacturing cost. Regrinding process is a typical treatment method for special tools or expensive tools. Tools that can be reground or recoated include drill bits, milling cutters, hobs and forming tools.

Tool regrinding

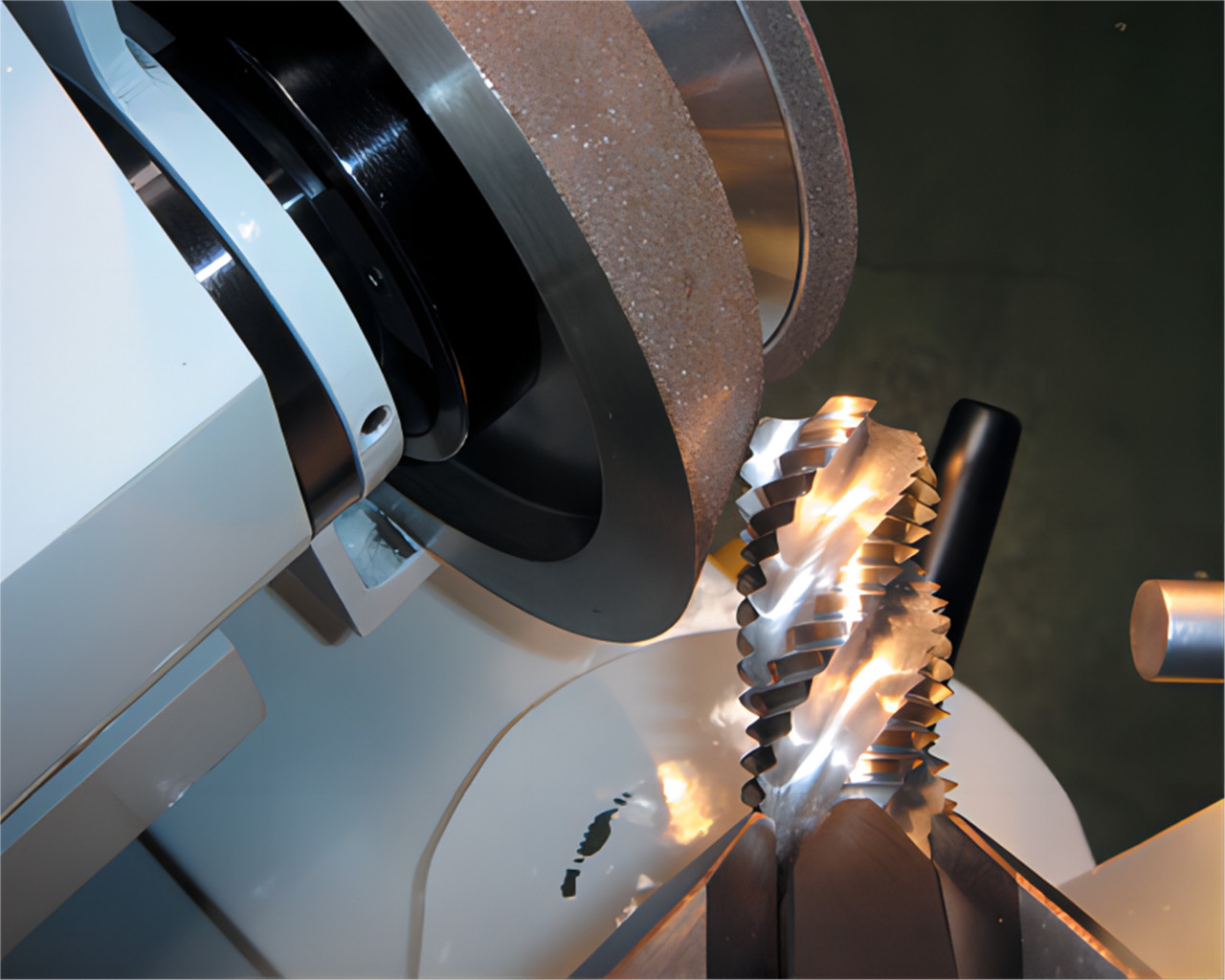

In the regrinding process of drill or milling cutter, it is necessary to grind the cutting edge to remove the original coating, so the grinding wheel used must have sufficient hardness. The pre-processing of the cutting edge by regrinding is very important. It is not only necessary to ensure that the geometric shape of the original cutting edge can be completely and accurately retained after the tool regrinding, but also requires that the PVD coated tool must be "safe" for regrinding. Therefore, it is necessary to avoid unreasonable grinding process (such as rough grinding or dry grinding, where the surface of the tool is damaged due to high temperature).

Removal of coating

Before the tool is recoated, all the original coatings can be removed by chemical methods. Chemical removal method is often used for complex tools (such as hobs and broaches), or tools with multiple recoating and tools with problems caused by coating thickness. The method of chemical removal of coating is usually limited to high-speed steel tools, because this method will damage the cemented carbide substrate: the method of chemical removal of coating will filter cobalt from the cemented carbide substrate, resulting in the surface porosity of the substrate, the formation of pores and the difficulty of recoating.

"Chemical removal method is preferred for corrosion removal of hard coatings on high-speed steel." Because the cemented carbide matrix contains chemical components similar to those in the coating, the chemical removal solvent is more likely to damage the cemented carbide matrix than the high-speed steel matrix.

In addition, there are some patented chemical methods suitable for removing PVD coating. In these chemical methods, there is only slight chemical reaction between the coating removal solution and the cemented carbide matrix, but these methods have not been widely used at present. In addition, there are other methods for cleaning the coating, such as laser processing, abrasive blasting, etc. Chemical removal method is the most common method, because it can provide good uniformity of surface coating removal.

At present, the typical recoating process is to remove the original coating of the tool through the regrinding process.

Economy of recoating

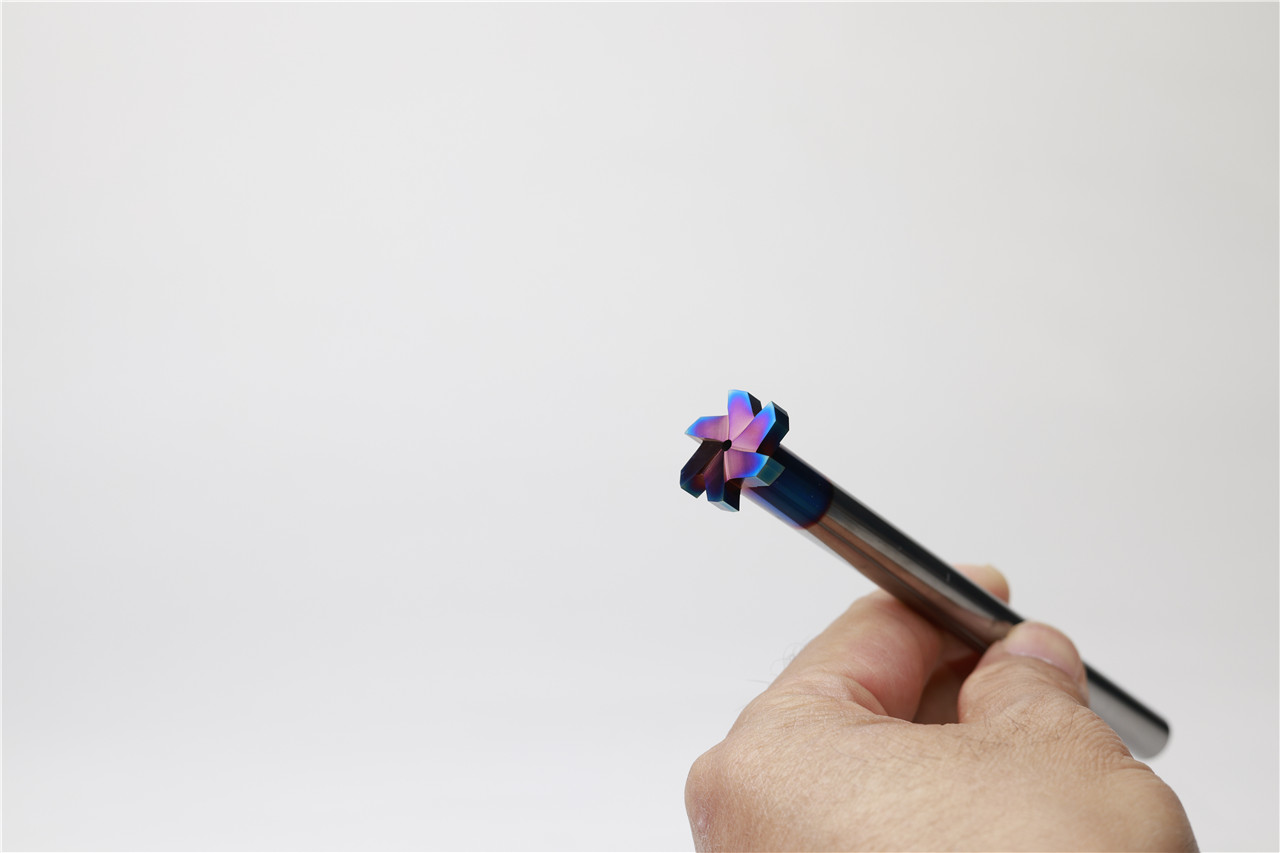

The most common tool coatings are TiN, TiC and TiAlN. Other superhard nitrogen/carbide coatings have also been applied, but are not very common. PVD diamond coated tools can also be reground and recoated. During the re-coating process, the tool shall be "protected" to avoid damage to the critical surface.

This is often the case: after purchasing uncoated tools, users can coat them when they need to be reground, or apply different coatings on new tools or reground tools.

Limitation of recoating

Just as a tool can be reground many times, the cutting edge of the tool can also be coated many times. The key to improve the tool performance is to obtain a coating with good adhesion on the surface of the tool that has been reground.

Except for the cutting edge, the rest of the tool surface may not need to be coated or recoated during each grinding of the tool, depending on the type of tool and the cutting parameters used in the machining. Hobs and broaches are tools that need to remove all the original coating when recoating, otherwise the tool performance will be reduced. Before the adhesion problem caused by stress becomes prominent, the tool can be recoated a few times without removing the old coating. Although PVD coating has residual compressive stress beneficial to metal cutting, this pressure will increase with the increase of coating thickness, and the coating will start to delaminate after exceeding a fixed limit. When recoating without removing the old coating, a thickness is added to the outer diameter of the tool. For the drill bit, it means that the hole diameter is getting larger. Therefore, it is necessary to consider the influence of the additional thickness of the coating on the outside diameter of the tool, as well as the influence of the two on the dimensional tolerance of the machined hole diameter.

A drill bit can be coated 5 to 10 times without removing the old coating, but after that, it will face serious error problems. Dennis Klein, vice president of Spec Tools, believed that the coating thickness would not be a problem within the error range of ± 1 µ m; However, when the error is within the range of 0.5~0.1 µ m, the influence of coating thickness must be considered. As long as the coating thickness does not become a problem, the recoated and reground tools may have better performance than the original ones.

Post time: Feb-24-2023