At present, China's machinery processing industry is developing rapidly, and some materials that are difficult to cut are widely used in the material industry and precision machinery industry. In order to meet the development needs of modern machinery processing industry, we need to use some tools with high strength and good toughness. Therefore, hard material tools are gradually applied to the mechanical processing industry. This article focuses on the application of hard material tools in machining in view of the development of hard material tools, so as to provide mutual reference for friends in the same industry.

With the rapid development of modern manufacturing technology and fierce market competition, the requirements of mechanical manufacturing industry for mechanical equipment parts are also increasing, especially for the structural performance of mechanical parts. Therefore, new materials with various properties have gradually emerged in the society. These new materials not only pose a serious challenge to traditional machining tools, but also are quite difficult to process. At this time, advanced cutting tools have become the key to the development of mechanical processing industry, and hard material tools have undoubtedly been applied to modern mechanical processing.

1. Development history of hard material tools

In the 1950s, American scientists took synthetic diamond, bond, and boron carbide powder as raw materials, reacted under high temperature and pressure, and sintered polycrystalline block as the main material of the tool. After the 1970s, people gradually developed composite sheet materials, which are produced by combining diamond and cemented carbide, or boron nitride and cemented carbide. In this technology, cemented carbide is regarded as the substrate, and a layer of diamond is formed on the surface of the substrate by pressing or sintering. The diamond is about 0.5 to 1 mm thick. Such materials can not only improve the bending resistance of materials, but also effectively solve the problem that traditional materials are not easy to weld. This has promoted the hard material tool to enter the application stage.

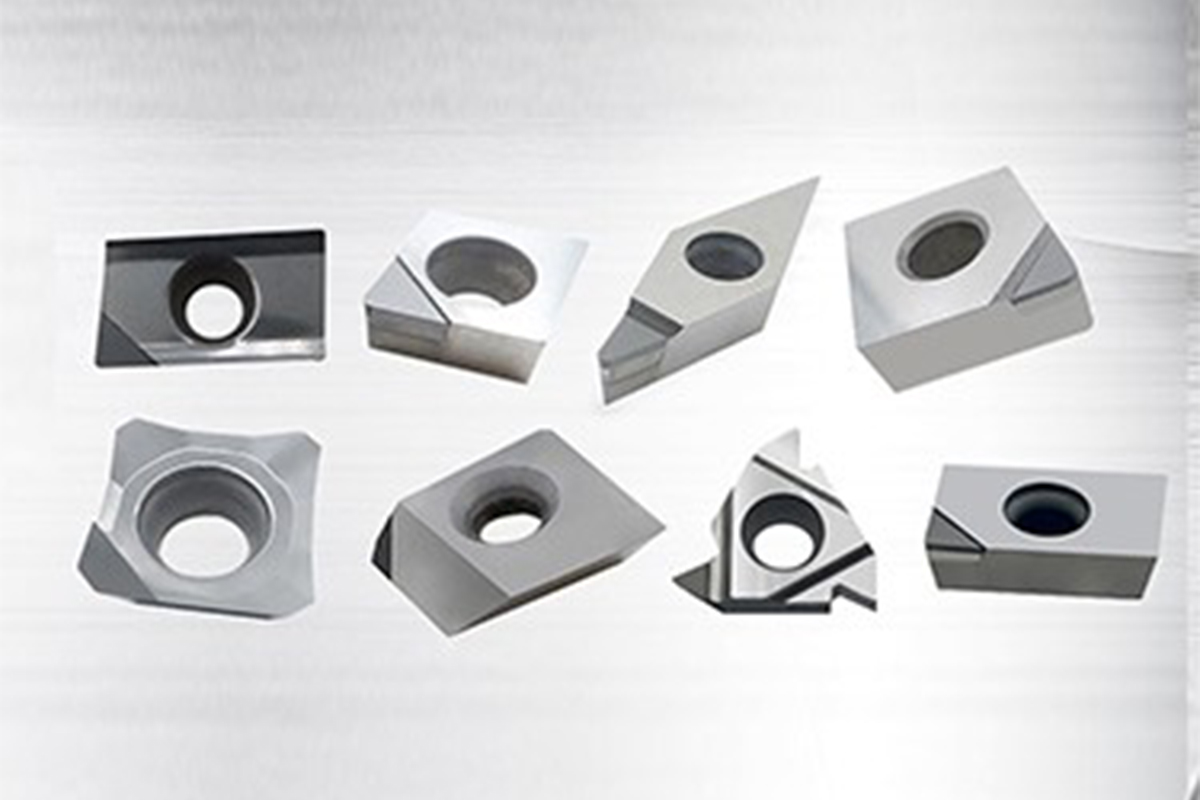

2. Application of hard material tools in machining

(1) Application of single crystal diamond tools

Single crystal diamond is usually divided into synthetic diamond and natural diamond. Generally, if single crystal diamond is used to make the tool, it is necessary to select the diamond with larger particle size, mass greater than 0.1 g and diameter length greater than 3 mm. At present, natural diamond is the hardest material in minerals. It not only has good wear resistance, but also the tool made of it is very sharp. At the same time, it has high adhesion resistance and low thermal conductivity. The tool processed is smooth and of good quality. At the same time, the tool made of natural diamond has very good durability and relatively long service life. In addition, when cutting for a long time, it will hardly affect the processing of parts. The relatively low thermal conductivity can have a good effect on preventing the deformation of parts.

Natural diamond has many advantages. Although these advantages are expensive, they can meet the requirements of many high-precision cutting operations and are widely used in precision cutting and ultra-precision cutting. Such as reflecting mirrors that use atomic reactors and other advanced technologies, as well as ground navigation gyroscopes used on missiles or rockets, as well as some watch parts, metal accessories, etc., have applied this technology.

(2) Application of polycrystalline diamond tools

Polycrystalline diamond is usually called sintered diamond. The use of polycrystalline diamond for metals such as cobalt, through the high temperature and high pressure conditions, will make a lot of diamond single crystal powder polycrystalline into one, thus forming a polycrystalline tool material. The hardness of polycrystalline diamond is lower than that of natural diamond. However, it is formed by a variety of diamond powder, and there is no case that different crystal planes have different strength and hardness. When cutting, the cutting edge made of polycrystalline diamond has a very high resistance to accidental damage and good wear resistance. It can keep the cutting edge sharp for a relatively long time. At the same time, it can use relatively fast cutting speed when machining. Compared with WC cemented carbide tools, polycrystalline diamond tools have longer service life, easier access to synthetic materials and lower prices.

(3) Application of CVD diamond

The tool material of CVD diamond is processed under low pressure, which is the biggest difference from the traditional PSC technology and PDC technology. CVD diamond does not contain any catalyst component. Although it is similar to natural diamond in some properties, it is still the same as polycrystalline diamond in materials, that is, the composition grains are disorderly arranged, lack of brittle cleavage surface, and have the same properties between surfaces. Compared with tools made by traditional technology, tools made by CVD diamond technology have more advantages, such as more complex tool shape, lower production cost, and multiple blades of the same blade.

(4) Application of polycrystalline cubic boron nitride

Polycrystalline cubic boron nitride (PCBN) is a very common hard material tool, which is more and more widely used in machining. The tool made with this technology has excellent hardness and wear resistance. It can not only be used at relatively high temperatures, but also has excellent corrosion resistance and thermal conductivity. Compared with PCD and PDC tools, polycrystalline cubic boron nitride tools are still inferior in wear resistance, but they can be used normally at 1200 ℃ and can withstand certain chemical corrosion!

At present, polycrystalline cubic boron nitride is mainly used in automobile manufacturing, such as automobile engines, transmission shafts, and brake discs. In addition, about one fifth of heavy equipment processing also uses this technology. In recent years, with the development of computer technology and CNC machine tool technology, the application of polycrystalline cubic boron nitride has become increasingly widespread, and with the implementation of advanced machining concepts such as high-speed cutting, turning instead of grinding, the tool material of polycrystalline cubic boron nitride has gradually developed into an important material in modern turning processing.

3. Summary

The application of hard material tools in machining not only improves the quality and efficiency of machining, but also plays a vital role in the development of mechanical processing industry. Therefore, in order to promote the development of the mechanical processing industry, it is necessary to continuously strengthen the research of hard material tools, fully understand the knowledge related to hard material tools, and strengthen the application practice, not only to improve the quality of staff, but also to strengthen the application of science and technology in improving hard material tools, so as to realize the leapfrog development of the mechanical processing industry.

Post time: Jun-03-2019