High speed steel extrusion tap

Product application

Tapping is suitable for connecting parts of various industries and teeth of various materials. For example, automobile engine, aircraft manufacturing, household appliances manufacturing, mobile phone manufacturing, etc., all need to attack teeth! How to choose a good tap supplier, very important!

According to different materials being processed, we can design different extrusion taps! You can use cobalt high speed steel taps or hard alloy taps, you can also use high speed steel taps, you can also choose powder metallurgy high speed steel taps! Tap construction can be cold inside or cold outside! With or without grooves!

There are many kinds of taps, the range of application is different! Especially extrusion tap, the bottom hole requirements are very come, if you have any questions about the tap, you can also find our customer service staff, ask for more detailed information, we can provide you with more detailed and professional answers!

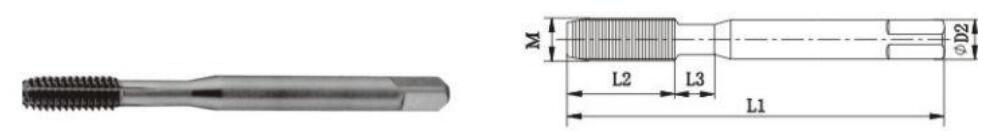

4505 Thread forming taps with reinforced shank

|

Size |

Pitch |

O.A.L |

Thread Lenath |

Shank Dia. |

Neck lenath |

Model No. |

|

|

M |

P |

L1 |

L2 |

D2 |

L3 |

Uncoated |

Coated |

|

M5 |

0.80 |

58 |

16 |

5.0 |

9 |

4505-050E |

■4505T-050E |

|

M5X0.5 |

0.50 |

58 |

16 |

5.0 |

9 |

4505-050A |

■4505T-050A |

|

M5.5X0.5 |

0.50 |

62 |

17 |

5.6 |

9 |

4505-055A |

■4505T-055A |

|

M6 |

1.00 |

66 |

19 |

6.3 |

11 |

4505-060F |

■4505T-060F |

|

M6X0.5 |

0.50 |

66 |

19 |

6.3 |

11 |

4505-060A |

■4505T-060A |

|

M6X0.75 |

0.75 |

66 |

19 |

6.3 |

11 |

4505-060D |

■4505T-060D |

|

M7 |

1.00 |

66 |

19 |

7.1 |

11 |

4505-070F |

■4505T-070F |

|

M7X0.75 |

0.75 |

66 |

19 |

7.1 |

11 |

4505-070D |

■4505T-070D |

|

M8 |

1.25 |

72 |

22 |

8.0 |

13 |

4505-080G |

■4505T-080G |

|

M8X0.5 |

0.60 |

66 |

19 |

8.0 |

13 |

4505-080A |

■4505T-080A |

|

M8X0.75 |

0.75 |

69 |

19 |

8.0 |

13 |

4606-080D |

■4505T-080D |

|

M8X1 |

1.00 |

69 |

19 |

8.0 |

13 |

4605-080F |

■4505T-080F |

|

M9 |

1.25 |

72 |

22 |

9.0 |

14 |

4505-090G |

■4505T-090G |

|

M9X0.75 |

0.75 |

66 |

19 |

9.0 |

14 |

4505-090D |

■4505T-090D |

|

M9X1 |

1.00 |

69 |

19 |

9.0 |

14 |

4505-090F |

■4505T-090F |

|

M10 |

1.60 |

80 |

24 |

10.0 |

15 |

4606-100H |

■4505T-100H |

|

M 10X0.75 |

0.75 |

73 |

20 |

10.0 |

15 |

4605-100D |

■4505T-100D |

|

M10X1 |

1.00 |

76 |

20 |

10.0 |

15 |

4606-100F |

■4505T-100F |

|

M10X1.25 |

1.25 |

76 |

20 |

10.0 |

15 |

4505-100G |

■4505T-100G |

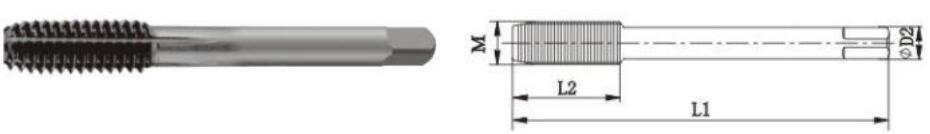

Thread forming taps with reduced shank 4605

|

Size |

Pitch |

O.A.L |

Thread length |

Shank Dia |

Model No. |

|

|

M |

P |

L1 |

L2 |

D2 |

Uncoated |

Coated |

|

M5 |

0.80 |

58 |

16 |

4.0 |

4605-050E |

4605T-050E |

|

M5X0.5 |

0.50 |

68 |

16 |

4.0 |

4605-050A |

■4605T-060A |

|

M5.5X0.5 |

0.50 |

62 |

17 |

4.0 |

4605-055A |

■4605T-055A |

|

M6 |

1.00 |

66 |

19 |

4.5 |

4605-060F |

■4605T-060F |

|

M6X0.75 |

0.75 |

66 |

19 |

4.5 |

4605-060D |

■4605T-060D |

|

M7 |

1.00 |

66 |

19 |

5.6 |

4605-070F |

■4605T-070F |

|

M7X0.75 |

0.75 |

66 |

19 |

5.6 |

4605-070D |

■4605T-070D |

|

M8 |

1.25 |

72 |

22 |

6.3 |

4605-080G |

4605T-080G |

|

M8X0.75 |

0.75 |

66 |

19 |

6.3 |

4606-080D |

■4605T-080D |

|

M8X1 |

1.00 |

69 |

19 |

6.3 |

4606-080F |

■4605T-080F |

|

M9 |

1.25 |

72 |

22 |

7.1 |

4606-090G |

■4605T-090G |

|

M9X0.75 |

1.00 |

66 |

19 |

7.1 |

4605-090D |

■4605T-090D |

|

M9X1 |

1.00 |

69 |

19 |

7.1 |

4605-090F |

■4605T-090F |

|

M10 |

1.50 |

80 |

24 |

8.0 |

4605-100H |

■4605T-100H |

|

M10X0.75 |

0.75 |

73 |

20 |

8.0 |

4605-100D |

■4605T-100D |

|

M10X1 |

1.00 |

76 |

20 |

8.0 |

4605-100F |

■4605T-100F |

|

M10X1.25 |

1.25 |

76 |

20 |

8.0 |

4605-100G |

■4605T-100G |

|

M11 |

1.50 |

85 |

25 |

8.0 |

4605-110H |

■4605T-110H |

|

M11X0.75 |

0.75 |

80 |

22 |

8.0 |

4605-110D |

■4605T-110D |

|

M11X1 |

1.00 |

80 |

22 |

8.0 |

4606-110F |

■4605T-110F |

|

M12 |

1.75 |

89 |

29 |

9.0 |

4605-1201 |

■4605T-1201 |

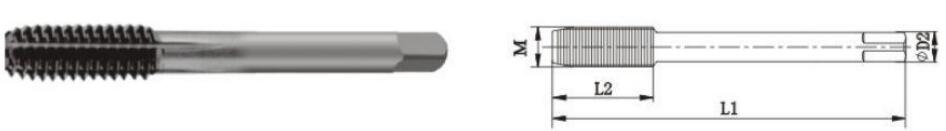

Thread forming taps with reduced shank 4605

|

Size |

Pitch |

O.A.L |

Thread length |

Shank Dia |

Model No. |

|

|

M |

P |

L1 |

L2 |

D2 |

Uncoated |

Coated |

|

M12X1 |

1.00 |

80 |

22 |

9.0 |

4605-120F |

■ 4605T-120F |

|

M12X1.25 |

1.25 |

84 |

24 |

9.0 |

4605-120G |

■4605T-120G |

|

M12X1.5 |

1.50 |

89 |

29 |

9.0 |

4605-120H |

■4605T-120H |

|

M14 |

2.00 |

95 |

30 |

11.2 |

4605-140J |

■4605T-140J |

|

M14X1 |

1.00 |

87 |

22 |

11.2 |

4605-140F |

■4605T-14OF |

|

M14X1.25 |

1.25 |

90 |

25 |

11.2 |

4605-140G |

■4605T-140G |

|

M14X1.5 |

1.50 |

96 |

30 |

11.2 |

4605-140H |

■4605T-140H |

|

M15X1.5 |

1.60 |

96 |

30 |

11.2 |

4605-150H |

■4605T-150H |

|

M16 |

2.00 |

102 |

32 |

12.5 |

4605-160J |

■4605T-160J |

|

M16X1 |

1.00 |

92 |

22 |

12.5 |

4605-160F |

■4605T-16OF |

|

M16X1.5 |

1.60 |

102 |

32 |

12.5 |

4605-160H |

■4605T-160H |

|

M17X1.5 |

1.60 |

102 |

32 |

12.5 |

4605-170H |

■4605T-170H |

|

M18 |

2.60 |

112 |

37 |

14.0 |

4605-180K |

■4605T-180K |

|

M18X1 |

1.00 |

97 |

22 |

14.0 |

4605-180F |

■4605T-180F |

|

M18X1.5 |

1.50 |

104 |

29 |

14.0 |

4605-180H |

■4605T-18OH |

|

M18X2 |

2.00 |

112 |

37 |

14.0 |

4605-180J |

■4605T-18OJ |

|

M20 |

2.50 |

112 |

37 |

14.0 |

4605-200K |

■4605T-200K |

|

M20X1 |

1.00 |

102 |

22 |

14.0 |

4605-200F |

■4605T-200F |

|

M20X1.5 |

1.50 |

104 |

29 |

14.0 |

4605-200H |

■4605T-200H |