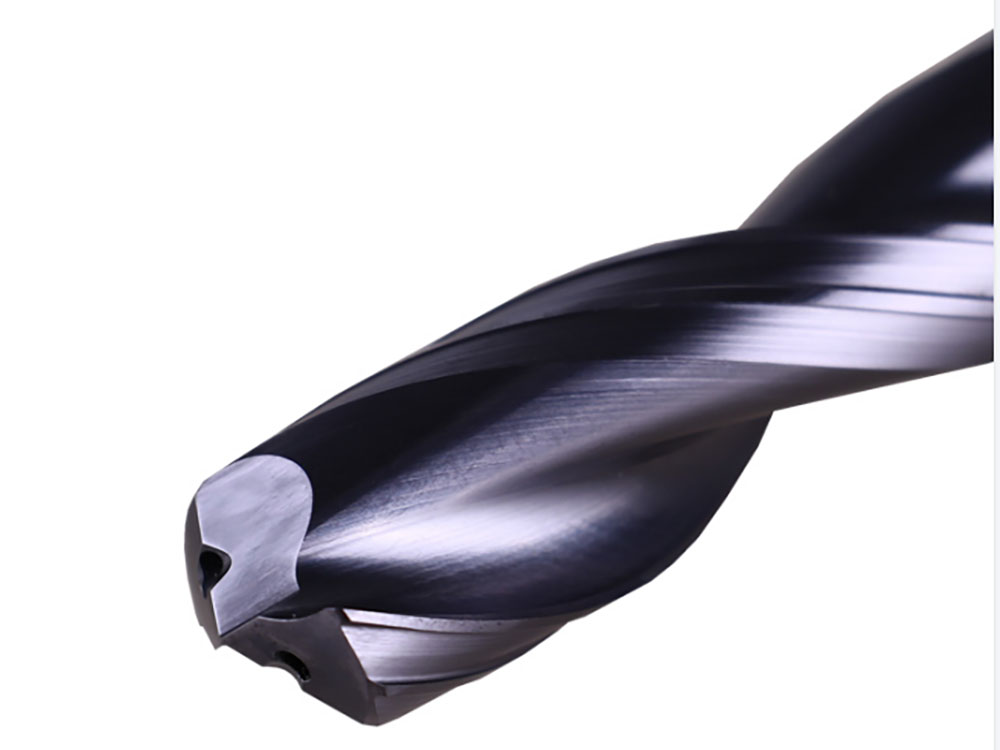

Internally cooled drill bit for deep hole machining

Product advantages

Compared with the less deep hole, the deep hole cooling and iron scrap removal is relatively difficult. It is necessary to control the breaking of iron scraps, but also to control the jumping amount and stability of the tool, otherwise the tool is easy to break the knife or the hole is not straight

Standard deep hole drill bit: Suitable for deep hole machining of steel, cast iron and other materials

| Bit diameter range d1(m7) | Drilling depth ratio (1/d) | Cooling mode | Shank form | Ordering model | Basic dimensions(mm) | remarks | ||||

| Shank diameter | Total length | Slot length | Recommended drilling depth | coating | ||||||

| d2(h6) | l1 | 12 | 13 | |||||||

| 3 ~3.5 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 6 | 90 | 50 | 40 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 6 | 123 | 83 | 72 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 6 | 160 | 120 | 108 | |||

| 3.6~4 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 6 | 90 | 50 | 40 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 6 | 136 | 96 | 84 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 6 | 176 | 136 | 124 | |||

| 4.1~4.5 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 6 | 102 | 64 | 56 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 6 | 148 | 108 | 96 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 6 | 192 | 152 | 140 | |||

| 4.6~4.9 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 6 | 102 | 64 | 56 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 6 | 158 | 118 | 106 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 6 | 208 | 168 | 156 | |||

| 5.0~5.5 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 6 | 116 | 78 | 72 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 6 | 168 | 128 | 116 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 6 | 228 | 188 | 170 | |||

| 5.6~6.0 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 6 | 116 | 78 | 72 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 6 | 180 | 140 | 126 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 6 | 240 | 200 | 182 | |||

| 6.1~6.5 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 8 | 131 | 93 | 82 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 8 | 190 | 150 | 132 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 8 | 260 | 220 | 202 | |||

| 6.6~7 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 8 | 131 | 92 | 83 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 8 | 202 | 160 | 143 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 8 | 270 | 230 | 213 | |||

| 7.1~ 7.5 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 8 | 145 | 108 | 95 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 8 | 213 | 172 | 155 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 8 | 290 | 250 | 230 | |||

| 7.6 ~8 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 8 | 146 | 108 | 96 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 8 | 223 | 183 | 163 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 8 | 305 | 263 | 245 | |||

| 8.1~8.5 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 10 | 160 | 120 | 107 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 10 | 239 | 195 | 175 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 10 | 330 | 285 | 263 | |||

| 8.6~9.0 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 10 | 162 | 120 | 108 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 10 | 249 | 205 | 185 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 10 | 340 | 295 | 276 | |||

| 9.1~9.5 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 10 | 174 | 131 | 120 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 10 | 262 | 217 | 195 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 10 | 360 | 315 | 291 | |||

| 9.6~10 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 10 | 174 | 132 | 120 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 10 | 272 | 228 | 206 | |||

| 30 | Internal cooling | Straight shank | d1*l3*d2*l1*30D | 10 | 372 | 328 | 305 | |||

| 10.1~10.5 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 12 | 204 | 156 | 144 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 12 | 292 | 242 | 220 | |||

| 10.6~11 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 12 | 204 | 156 | 144 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 12 | 300 | 250 | 228 | |||

| 11.1~12 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 12 | 204 | 156 | 144 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 12 | 325 | 275 | 250 | |||

| 12~ 13 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 14 | 230 | 182 | 168 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 14 | 338 | 290 | 265 | |||

| 13.1~ 14 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 14 | 230 | 182 | 168 | ||

| 20 | Internal cooling | Straight shank | d1*l3*d2*l1*20D | 14 | 367 | 318 | 290 | |||

| 14.1~ 16 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 14 | 260 | 208 | 194 | ||

| 16.1~18 | 12 | Internal cooling | Straight shank | d1*l3*d2*l1*12D | 14 | 286 | 234 | 218 | ||

| Applicable table of processed materials | very suitable | suitable | ||||||||

| number | Processed materials | |||||||||

| Mild steel HB≤180 | Carbon and alloy steels | Pre hardened steel, hardened steel | stainless steel | cast iron | Ductile iron | aluminium alloy | heat-resisting alloy | |||

| ~40HRC | ~50HRC | ~60HRC | ||||||||

remarks

1.The handle is straight by default. If you need other handle standards, please refer to our handle materials or drawings for confirmation;

2. The default top angle is 140 or 135 degrees. If other angles are required, please mark or refer to the drawing;

3. If the order parameters are inconsistent with our company’s, you can inform our customer service personnel, and we will be enthusiastic to provide you with drawings for confirmation;