Tapping hardened steel Best carbide taps for hardened steel M, UNC,BSP taps

- Description

Mold and die industry often have to tapping hardened materials, that require specific taps to handle high hardness steels.

OPT carbide machine tap and carbide hand tap set are designed for tapping hardened steel and extremely high hardness steel up to 63 HRC.

ISO standard, JIS standard, DIN standard carbide tap all avaialble and can be customized with short lead time.

OPT has been committed to thread machining in a variety of industries, according to customer application matching machining solutions, we also provide premium carbide drills and reamers for machining hardened steel.

Welcome to contact us to disscuss your project.

- Typical application

Tool materail: Considering wear resistance and impact resistance, ultra-fine tungsten carbide materials with reasonable hardness and toughness are used to ensure the durability of carbide taps

Geometry: To increase rigidity and prevent edge breakage, special rake angles are designed

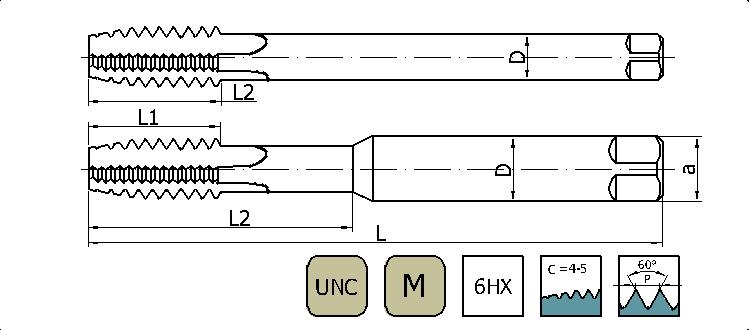

Chamfer length: Considering stability and toollife, the length of the cut in chamfer is usually 4-5 teeth

Machine: Suggest to use a machine tool with low vibration and the ability to choose a reasonable feed rate to achieve stable tapping

Bottom hole: Drill the bottom hole as large as possible within thread tolerance because it helps reduce the torque load and tapping becomes longer life.

Inspection and display

Before ordering, please communicate with our pre-sales customer service:

1. Workpiece material

2. Whether product is surface treated after processing

3. Accuracy requirements, size of go gauge and no go gauge.

| ltem No. | Product specifications | L1 | L2 | L | D | a | Z | Limit |

| T605-040050 | M3x0.5 | 11 | 18 | 50 | 4 | 3.15 | 4 | H2 |

| T605-050050 | M4x0.5 | 13 | 21 | 53 | 5 | 4 | 4 | H2 |

| T605-050053 | M4x0.7 | 13 | 21 | 53 | 5 | 4 | 4 | H2 |

| T604-050053 | M4x0.7 | 13 | 21 | 53 | 5 | 4 | 4 | H2 |

| T604-060058 | M5x0.8 | 16 | 25 | 58 | 6 | 4.5 | 4 | H2 |

| T605-060058 | M5x0.8 | 16 | 25 | 58 | 6 | 4.5 | 4 | H2 |

| T605-060066 | M6x1 | 19 | 30 | 66 | 6 | 4.5 | 4 | H2 |

| T604-060066 | M6x1 | 19 | 30 | 66 | 6 | 4.5 | 4 | H2 |

| T604–UNC1/4-20 | UNC1/4-20 | 19 | 30 | 66 | 6 | 4.5 | 4 | H2 |

| T604–UNC5/1618 | UNC5/16-18 | 22 | 35 | 72 | 8 | 6.3 | 5 | H2 |

| T604-080072 | M8x1.25 | 22 | 35 | 72 | 8 | 6.3 | 5 | H2 |

| T605-080072 | M8x1.25 | 22 | 35 | 72 | 8 | 6.3 | 5 | H2 |

| T605-080080 | M10x1.5 | 24 | 24 | 80 | 8 | 6.3 | 5 | H2 |

| T604-080080 | M10x1.5 | 24 | 24 | 80 | 8 | 6.3 | 5 | H2 |

| T604–UNC3/816 | UNC3/8-16 | 24 | 38 | 80 | 8 | 6.3 | 5 | H2 |

| T604–UNC7/1614 | UNC7/16-14 | 25 | 40 | 85 | 10 | 8 | 5 | H2 |

| T604–UNC1/213 | UNC1/2-13 | 29 | 29 | 89 | 10 | 8 | 5 | H2 |

| T604-100089 | M12x1.75 | 29 | 46 | 89 | 10 | 8 | 5 | H2 |

| T605-100089 | M12x1.75 | 29 | 46 | 89 | 10 | 8 | 5 | H2 |

| T604–UNC9/1612 | UNC9/16-12 | 30 | 30 | 95 | 12 | 10 | 6 | H2 |