Carbide machine tap Spiral flute tap Solid carbide taps for aluminum

Features:

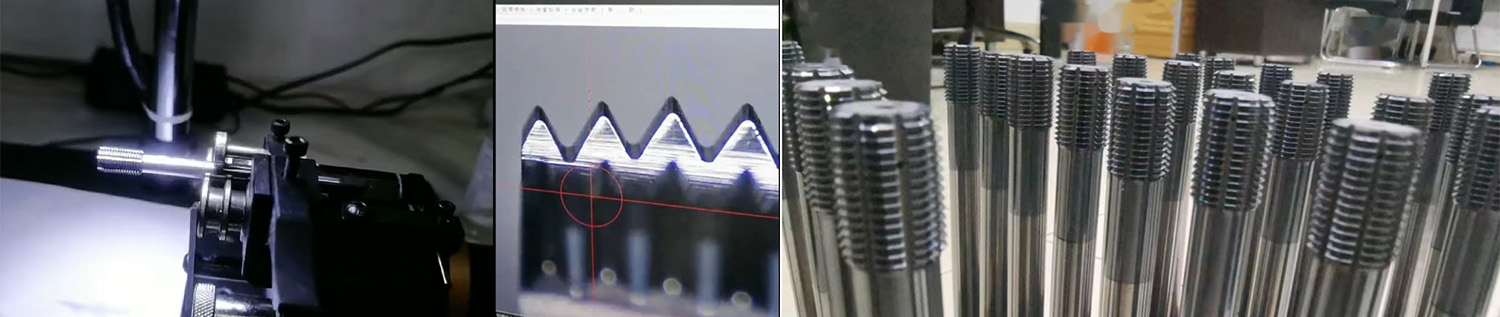

1. Superior Chip Evacuation: Preventing chip jamming, and facilitating a smooth machining process.

2. Extended Tool Life: Thanks to premium carbide material, spiral carbide taps exhibit exceptional wear resistance, resulting in a longer tool life and reduced cutting tool replacement costs.

3. Enhanced Surface Finish: The precise cutting geometry of spiral carbide taps allows for clean and accurate machining, resulting in improved surface finish and dimensional accuracy of machined aluminum components.

4. Increased Machining Speed: With the optimized chip evacuation and heat dissipation provided by spiral carbide taps, higher cutting speeds can be achieved without compromising tool life or workpiece integrity.

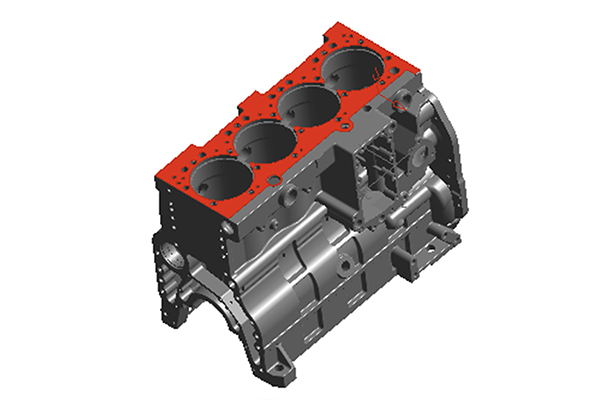

Typical application 02

Aerospace Industry: Aluminum alloys play a vital role in aircraft manufacturing, and spiral carbide taps are essential for creating precision parts for aircraft engines, wing structures, and frames.

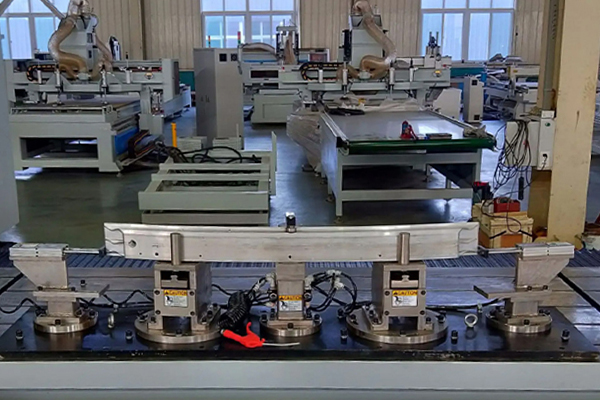

Typical application 03

Electronics Industry: With the increasing demand for lightweight electronic devices, aluminum is frequently used in the production of casings and heat sinks. Spiral carbide taps ensure accurate machining and uniform threads in these applications.

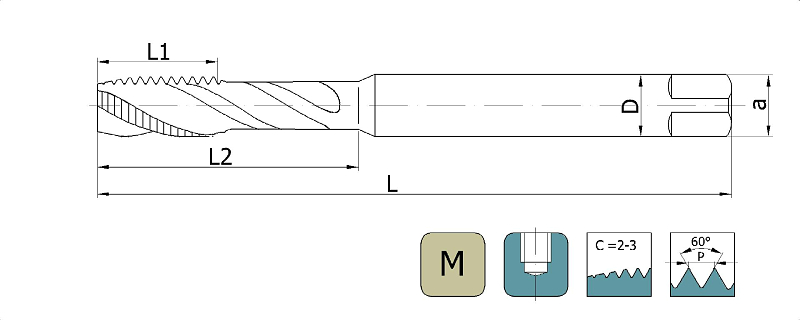

| ltemNo. | Product specifications | L1 | L2 | L | D | a | Z | Limit | Standard |

| SPS040070 | M4×0.7 | 13 | 21 | 63 | 4.5 | 3.4 | 3 | P2 | DIN |

| SPS050080 | M5×0.8 | 15 | 25 | 70 | 6 | 4.9 | 3 | P2 | DIN |

| SPS080100 | M8×1 | 16 | 35 | 90 | 8 | 6.2 | 3 | P3 | DIN |

| SPS080125 | M8×1.25 | 16 | 35 | 90 | 8 | 6.2 | 3 | P3 | DIN |

| SPS060100 | M6×1 | 17 | 30 | 80 | 6 | 4.9 | 3 | P2 | DIN |

| SPS070100 | M7×1 | 17 | 30 | 80 | 7 | 5.5 | 3 | P3 | DIN |

| SPS160125 | M16×1.25 | 18 | 18 | 110 | 12 | 9 | 3 | P3 | DIN |

| SPS100150 | M10×1.5 | 18 | 39 | 90 | 10 | 8 | 3 | P4 | DIN |

| SPS100125 | M10×1.25 | 18 | 39 | 90 | 10 | 8 | 3 | P3 | DIN |

| SPS120175 | M12×1.75 | 22 | 22 | 110 | 9 | 7 | 3 | P4 | DIN |

| SPS120150 | M12×1.5 | 22 | 22 | 110 | 9 | 7 | 3 | P4 | DIN |

| SPS120125 | M12×1.25 | 22 | 22 | 110 | 9 | 7 | 3 | P3 | DIN |

| SPS140150 | M14×1.5 | 22 | 22 | 110 | 11 | 9 | 3 | P4 | DIN |

| SPS140125 | M14×1.25 | 22 | 22 | 110 | 11 | 9 | 3 | P3 | DIN |

| SPS160150 | M16×1.5 | 22 | 22 | 110 | 12 | 9 | 3 | P4 | DIN |

| SPS180150 | M18×1.5 | 25 | 25 | 125 | 14 | 11 | 4 | P4 | DIN |

| SPS200150 | M20×1.5 | 25 | 25 | 140 | 16 | 12 | 4 | P4 | DIN |

| SPS220150 | M22×1.5 | 25 | 25 | 140 | 18 | 14.5 | 4 | P4 | DIN |

| SPS180200 | M18×2 | 26 | 26 | 125 | 14 | 11 | 4 | P5 | DIN |

| SPS140200 | M14×2 | 26 | 26 | 110 | 11 | 9 | 3 | P5 | DIN |

| SPS160200 | M16×2 | 27 | 27 | 110 | 12 | 9 | 3 | P5 | DIN |

| SPS200200 | M20×2 | 27 | 27 | 140 | 16 | 12 | 4 | P5 | DIN |

| SPS220200 | M22×2 | 27 | 27 | 140 | 18 | 14.5 | 4 | P5 | DIN |

| SPS240200 | M24×2 | 27 | 27 | 140 | 18 | 14.5 | 4 | P5 | DIN |

| SPS240150 | M24×1.5 | 27 | 27 | 140 | 18 | 14.5 | 4 | P4 | DIN |

| SPS180250 | M18×2.5 | 30 | 30 | 125 | 14 | 11 | 4 | P6 | DIN |

| SPS220250 | M22×2.5 | 32 | 32 | 140 | 18 | 14.5 | 4 | P6 | DIN |

| SPS200250 | M20×2.5 | 32 | 32 | 140 | 16 | 12 | 4 | P6 | DIN |

| SPS240300 | M24×3 | 34 | 34 | 140 | 18 | 14.5 | 4 | P6 | DIN |

| SPS270300 | M27×3 | 36 | 36 | 160 | 20 | 16 | 4 | P6 | DIN |

| SPS300350 | M30×3.5 | 40 | 40 | 180 | 22 | 18 | 4 | P7 | DIN |