Carbide Taps, Threading tools-tap and dies, carbide tap for hardened steel

Product application range

Teeth are used in all industries of connection pieces, all kinds of materials to tap teeth! For example, automobile engine, aircraft manufacturing, home appliances manufacturing, mobile phone manufacturing, etc., all need to attack teeth! How to choose a good tap supplier, very important!

Comparative advantages of peers

· OPT taps are unique: more than 25 years of production technology;

· OPT uses coatings 40% stronger than normal coatings;

· Our chip free extrusion taps and cutting taps, tungsten steel materials and powder metallurgy high speed steel materials, are first-class quality;

Technological advantage

When you have special requirements, such as the bottom need to avoid the hole, or the bottom need to drill, we can according to your production conditions, increase the hole on the tap, or increase the cutting edge of drilling and milling, in order to meet the different needs of different customers!

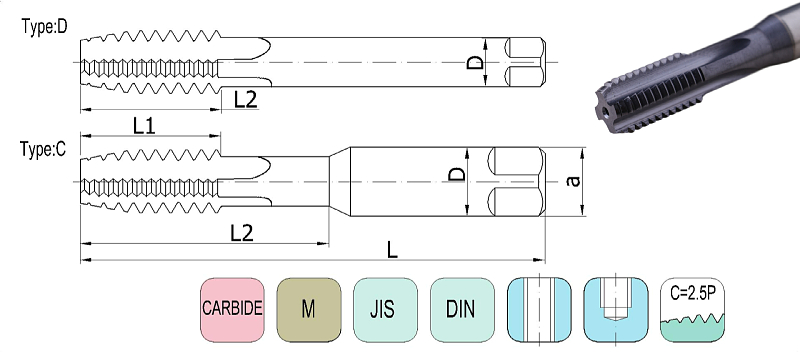

| LtemNo. | Productspecifications | L1 | L2 | L | D | a | Z | Limit | Standard |

| WDH050080 | M5×0.8 | 15 | 25 | 70 | 6 | 4.9 | 3 | P2 | DIN |

| WDH080100 | M8×1 | 16 | 35 | 80 | 8 | 6.2 | 4 | P3 | DIN |

| WDH080125 | M8×1.25 | 16 | 35 | 90 | 8 | 6.2 | 4 | P3 | DIN |

| WH050080 | M5*0.8 | 16 | 16 | 62 | 5.5 | 4.5 | 3 | P3 | JIS |

| WDH060100 | M6×1 | 17 | 30 | 80 | 6 | 4.9 | 3 | P2 | DIN |

| WDH070100 | M7×1 | 17 | 30 | 80 | 7 | 5.5 | 3 | P3 | DIN |

| WDH160125 | M16×1.25 | 18 | 18 | 110 | 12 | 9 | 4 | P3 | DIN |

| WDH100150 | M10×1.5 | 18 | 39 | 90 | 10 | 8 | 4 | P4 | DIN |

| WDH100125 | M10×1.25 | 18 | 39 | 100 | 10 | 8 | 4 | P3 | DIN |

| WH060100 | M6×1 | 19 | 29 | 62 | 6 | 4.5 | 3 | P3 | JIS |

| WH140200 | M14×2 | 20 | 20 | 88 | 10.5 | 8 | 4 | P6 | JIS |

| WH140150 | M14×1.5 | 20 | 20 | 88 | 10.5 | 8 | 4 | P5 | JIS |

| WH160200 | M16×2 | 20 | 20 | 95 | 12.5 | 10 | 4 | P6 | JIS |

| WH160150 | M16×1.5 | 20 | 20 | 95 | 12.5 | 10 | 4 | P5 | JIS |

| WH080125 | M8×1.25 | 22 | 22 | 75 | 6.2 | 5 | 3 | P4 | JIS |

| WDH120175 | M12×1.75 | 22 | 22 | 110 | 9 | 7 | 4 | P4 | DIN |

| WDH120150 | M12×1.5 | 22 | 22 | 110 | 9 | 7 | 4 | P3 | DIN |

| WDH120125 | M12×1.25 | 22 | 22 | 110 | 9 | 7 | 4 | P3 | DIN |

| WDH160150 | M16×1.5 | 22 | 22 | 110 | 12 | 9 | 4 | P4 | DIN |

| WDH140150 | M14×1.5 | 22 | 22 | 110 | 11 | 9 | 4 | P4 | DIN |

| WDH140125 | M14×1.25 | 22 | 22 | 110 | 11 | 9 | 4 | P3 | DIN |

| WH100150 | M10×1.5 | 24 | 24 | 75 | 7 | 5.5 | 4 | P5 | JIS |

| MH100125 | M10×1.25 | 24 | 24 | 75 | 7 | 5.5 | 4 | P4 | JIS |

| WDH180150 | M18×1.5 | 25 | 25 | 125 | 14 | 11 | 4 | P4 | DIN |

| WDH200150 | M20×1.5 | 25 | 25 | 140 | 16 | 12 | 4 | P4 | DIN |

| WDH220150 | M22×1.5 | 25 | 25 | 140 | 18 | 14.5 | 4 | P4 | DIN |

| WDH180200 | M18×2 | 26 | 26 | 125 | 14 | 11 | 4 | P5 | DIN |

| WDH140200 | M14×2 | 26 | 26 | 110 | 11 | 9 | 4 | P5 | DIN |

| WDH160200 | M16×2 | 27 | 27 | 110 | 12 | 9 | 4 | P5 | DIN |

| WDH200200 | M20×2 | 27 | 27 | 140 | 16 | 12 | 4 | P5 | DIN |

| WDH220200 | M22×2 | 27 | 27 | 140 | 18 | 14.5 | 4 | P5 | DIN |

| WDH240200 | M24×2 | 27 | 27 | 140 | 18 | 14.5 | 4 | P5 | DIN |

| WDH240150 | M24×1.5 | 27 | 27 | 140 | 18 | 14.5 | 4 | P4 | DIN |

| WH120175 | M12×1.75 | 29 | 29 | 82 | 8.5 | 6.5 | 4 | P5 | JIS |

| WH120150 | M12×1.5 | 29 | 29 | 82 | 8.5 | 6.5 | 4 | P5 | JIS |

| WH120125 | M12×1.25 | 29 | 29 | 82 | 8.5 | 6.5 | 4 | P5 | JIS |

| WDH180250 | M18×2.5 | 30 | 30 | 125 | 14 | 11 | 4 | P6 | DIN |

| WDH220250 | M22×2.5 | 32 | 32 | 140 | 18 | 14.5 | 4 | P6 | DIN |

| WDH200250 | M20×2.5 | 32 | 32 | 140 | 16 | 12 | 4 | P6 | DIN |

| WDH240300 | M24×3 | 34 | 34 | 140 | 18 | 14.5 | 4 | P6 | DIN |

| WDH270300 | M27×3 | 36 | 36 | 160 | 20 | 16 | 4 | P6 | DIN |

| WDH300350 | M30×3.5 | 40 | 40 | 180 | 22 | 18 | 4 | P7 | DIN |