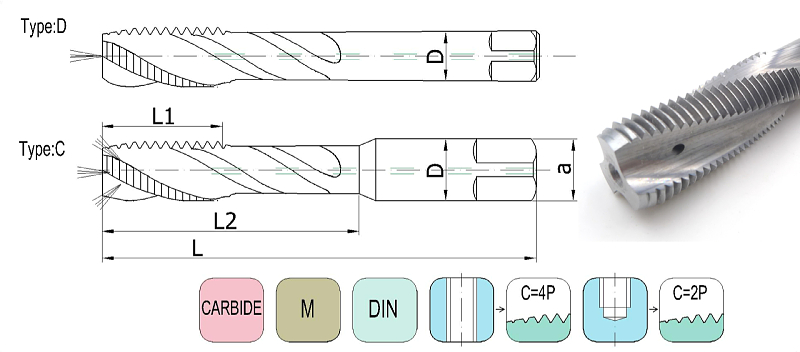

Sprial flute solid carbide taps for cast iron

Product advantages

Compared with steel, cast iron tungsten taps are relatively easy to work with. Because the iron chips of cast iron material are easier to control, the cutting edge is not easy to stick iron chips, so the tap life of cast iron material is relatively long. If the machine tool has internal cooling, try to use internal cooling tap, better life

◎Various coating selection, suitable for Aluminum alloy, Magnesium alloy,Copper alloy, Cast Aluminum, Cast Zinc alloy

| LtemNo. | Productspecifications | L1 | L2 | L | D | a | Z | Limit | Standard |

| SPS-Z040070 | M4×0.7 | 13 | 21 | 63 | 4.5 | 3.4 | 3 | P2 | DIN |

| SPS-C040070 | M4×0.7 | 13 | 21 | 63 | 4.5 | 3.4 | 3 | P2 | DIN |

| SPS-C050080 | M5×0.8 | 15 | 25 | 70 | 6 | 4.9 | 3 | P2 | DIN |

| SPS-Z050080 | M5×0.8 | 15 | 25 | 70 | 6 | 4.9 | 3 | P2 | DIN |

| SPS-Z080100 | M8×1 | 16 | 35 | 90 | 8 | 6.2 | 3 | P3 | DIN |

| SPS-Z080125 | M8×1.25 | 16 | 35 | 90 | 8 | 6.2 | 3 | P3 | DIN |

| SPS-C080100 | M8×1 | 16 | 35 | 90 | 8 | 6.2 | 3 | P3 | DIN |

| SPS-C080125 | M8×1.25 | 16 | 35 | 90 | 8 | 6.2 | 3 | P3 | DIN |

| SPS-C060100 | M6×1 | 17 | 30 | 80 | 6 | 4.9 | 3 | P2 | DIN |

| SPS-C070100 | M7×1 | 17 | 30 | 80 | 7 | 5.5 | 3 | P3 | DIN |

| SPS-Z060100 | M6×1 | 17 | 30 | 80 | 6 | 4.9 | 3 | P2 | DIN |

| SPS-Z070100 | M7×1 | 17 | 30 | 80 | 7 | 5.5 | 3 | P3 | DIN |

| SPS-Z160125 | M16×1.25 | 18 | 18 | 110 | 12 | 9 | 3 | P3 | DIN |

| SPS-Z100150 | M10×1.5 | 18 | 39 | 90 | 10 | 8 | 3 | P4 | DIN |

| SPS-Z100125 | M10×1.25 | 18 | 39 | 90 | 10 | 8 | 3 | P3 | DIN |

| SPS-C160125 | M16×1.25 | 18 | 18 | 110 | 12 | 9 | 3 | P3 | DIN |

| SPS-C100150 | M10×1.5 | 18 | 39 | 90 | 10 | 8 | 3 | P4 | DIN |

| SPS-C100125 | M10×1.25 | 18 | 39 | 90 | 10 | 8 | 3 | P3 | DIN |

| SPS-C120175 | M12×1.75 | 22 | 22 | 110 | 9 | 7 | 3 | P4 | DIN |

| SPS-C120150 | M12×1.5 | 22 | 22 | 110 | 9 | 7 | 3 | P4 | DIN |

| SPS-C120125 | M12×1.25 | 22 | 22 | 110 | 9 | 7 | 3 | P3 | DIN |

| SPS-C140150 | M14×1.5 | 22 | 22 | 110 | 11 | 9 | 3 | P4 | DIN |

| SPS-C140125 | M14×1.25 | 22 | 22 | 110 | 11 | 9 | 3 | P3 | DIN |

| SPS-C160150 | M16×1.5 | 22 | 22 | 110 | 12 | 9 | 3 | P4 | DIN |

| SPS-Z120175 | M12×1.75 | 22 | 22 | 110 | 9 | 7 | 3 | P4 | DIN |

| SPS-Z120150 | M12×1.5 | 22 | 22 | 110 | 9 | 7 | 3 | P4 | DIN |

| SPS-Z120125 | M12×1.25 | 22 | 22 | 110 | 9 | 7 | 3 | P3 | DIN |

| SPS-Z140150 | M14×1.5 | 22 | 22 | 110 | 11 | 9 | 3 | P4 | DIN |

| SPS-Z140125 | M14×1.25 | 22 | 22 | 110 | 11 | 9 | 3 | P3 | DIN |

| SPS-Z160150 | M16×1.5 | 22 | 22 | 110 | 12 | 9 | 3 | P4 | DIN |

| SPS-Z180150 | M18×1.5 | 25 | 25 | 125 | 14 | 11 | 4 | P4 | DIN |

| SPS-Z200150 | M20×1.5 | 25 | 25 | 140 | 16 | 12 | 4 | P4 | DIN |

| SPS-Z220150 | M22×1.5 | 25 | 25 | 140 | 18 | 14.5 | 4 | P4 | DIN |

| SPS-C180150 | M18×1.5 | 25 | 25 | 125 | 14 | 11 | 4 | P4 | DIN |

| SPS-C200150 | M20×1.5 | 25 | 25 | 140 | 16 | 12 | 4 | P4 | DIN |

| SPS-C220150 | M22×1.5 | 25 | 25 | 140 | 18 | 14.5 | 4 | P4 | DIN |

| SPS-C180200 | M18×2 | 26 | 26 | 125 | 14 | 11 | 4 | P5 | DIN |

| SPS-C140200 | M14×2 | 26 | 26 | 110 | 11 | 9 | 3 | P5 | DIN |

| SPS-Z180200 | M18×2 | 26 | 26 | 125 | 14 | 11 | 4 | P5 | DIN |

| SPS-Z140200 | M14×2 | 26 | 26 | 110 | 11 | 9 | 3 | P5 | DIN |

| SPS-Z160200 | M16×2 | 27 | 27 | 110 | 12 | 9 | 3 | P5 | DIN |

| SPS-Z200200 | M20×2 | 27 | 27 | 140 | 16 | 12 | 4 | P5 | DIN |

| SPS-Z220200 | M22×2 | 27 | 27 | 140 | 18 | 14.5 | 4 | P5 | DIN |

| SPS-Z240200 | M24×2 | 27 | 27 | 140 | 18 | 14.5 | 4 | P5 | DIN |

| SPS-Z240150 | M24×1.5 | 27 | 27 | 140 | 18 | 14.5 | 4 | P4 | DIN |

| SPS-C160200 | M16×2 | 27 | 27 | 110 | 12 | 9 | 3 | P5 | DIN |

| SPS-C200200 | M20×2 | 27 | 27 | 140 | 16 | 12 | 4 | P5 | DIN |

| SPS-C220200 | M22×2 | 27 | 27 | 140 | 18 | 14.5 | 4 | P5 | DIN |

| SPS-C240200 | M24×2 | 27 | 27 | 140 | 18 | 14.5 | 4 | P5 | DIN |

| SPS-C240150 | M24×1.5 | 27 | 27 | 140 | 18 | 14.5 | 4 | P4 | DIN |

| SPS-C180250 | M18×2.5 | 30 | 30 | 125 | 14 | 11 | 4 | P6 | DIN |

| SPS-Z180250 | M18×2.5 | 30 | 30 | 125 | 14 | 11 | 4 | P6 | DIN |

| SPS-Z220250 | M22×2.5 | 32 | 32 | 140 | 18 | 14.5 | 4 | P6 | DIN |

| SPS-Z200250 | M20×2.5 | 32 | 32 | 140 | 16 | 12 | 4 | P6 | DIN |

| SPS-C220250 | M22×2.5 | 32 | 32 | 140 | 18 | 14.5 | 4 | P6 | DIN |

| SPS-C200250 | M20×2.5 | 32 | 32 | 140 | 16 | 12 | 4 | P6 | DIN |

| SPS-C240300 | M24×3 | 34 | 34 | 140 | 18 | 14.5 | 4 | P6 | DIN |

| SPS-Z240300 | M24×3 | 34 | 34 | 140 | 18 | 14.5 | 4 | P6 | DIN |

| SPS-Z270300 | M27×3 | 36 | 36 | 160 | 20 | 16 | 4 | P6 | DIN |

| SPS-C270300 | M27×3 | 36 | 36 | 160 | 20 | 16 | 4 | P6 | DIN |

| SPS-C300350 | M30×3.5 | 40 | 40 | 180 | 22 | 18 | 4 | P7 | DIN |

| SPS-Z300350 | M30×3.5 | 40 | 40 | 180 | 22 | 18 | 4 | P7 | DIN |

Write your message here and send it to us