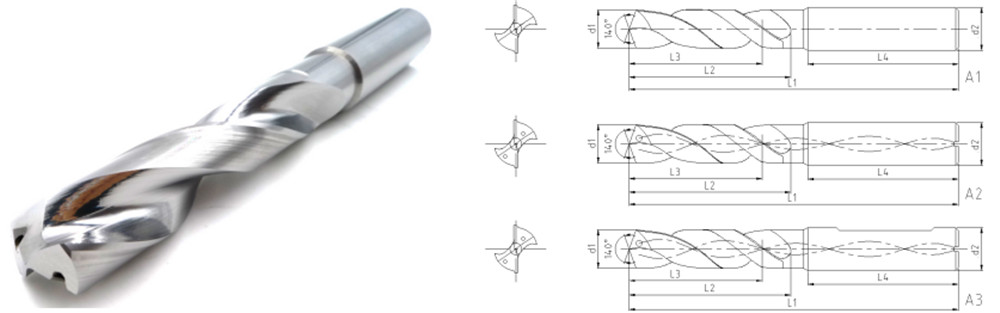

Drill bit for machining aluminum alloy material

Aluminum bit: Suitable for efficient drilling of various aluminum alloy materials

| Bit diameter range d1(m7) | Drilling depth ratio (1/d) | Cooling mode | Shank form | Ordering model | Basic dimensions(mm) | remarks | ||||

| Shank diameter | Total length | Slot length | Recommended drilling depth | coating | ||||||

| d2(h6) | l1 | 12 | 13 | |||||||

| 2 ~2.5 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 3 | 54 | 13 | 9 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 3 | 58 | 18 | 14 | |||

| 8 | External cooling | Straight shank | d1*l3*d2*l1*3D | 4 | 62 | 25 | 21 | |||

| 2.55~2.95 | 3 | External cooling | Straight shank | d1*l3*d2*l1*5D | 4 | 54 | 18 | 14 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*3D | 4 | 58 | 20 | 16 | |||

| 8 | External cooling | Straight shank | d1*l3*d2*l1*8D | 4 | 66 | 28 | 23 | |||

| 3.6~4 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 4 | 54 | 20 | 14 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 4 | 66 | 28 | 23 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D | 4 | 72 | 34 | 29 | |||

| 4~4.9 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 5 | 66 | 24 | 17 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 5 | 74 | 34 | 26 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D-C | 6 | 95 | 57 | 46 | |||

| 5~6.0 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 6 | 66 | 28 | 20 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 6 | 82 | 42 | 32 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D-C | 6 | 95 | 57 | 47 | |||

| 6.1~7 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 7 | 79 | 34 | 24 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 7 | 91 | 53 | 41 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D-C | 8 | 110 | 74 | 62 | |||

| 7.1~8 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 8 | 79 | 40 | 28 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 8 | 91 | 52 | 42 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D-C | 8 | 110 | 73 | 65 | |||

| 8.1~ 9 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 9 | 89 | 45 | 32 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 9 | 100 | 58 | 47 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D-C | 10 | 135 | 90 | 75 | |||

| 9.1~10 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 10 | 89 | 46 | 35 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 10 | 100 | 60 | 49 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D | 10 | 140 | 95 | 82 | |||

| 10.1~12 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 11 | 100 | 55 | 40 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 11 | 116 | 70 | 56 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D-C | 12 | 160 | 113 | 98 | |||

| 12.1~14 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 14 | 107 | 60 | 45 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 14 | 124 | 77 | 60 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D-C | 14 | 178 | 133 | 116 | |||

| 14.1~16 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 16 | 110 | 62 | 46 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 16 | 133 | 90 | 75 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D-C | 16 | 200 | 156 | 130 | |||

| 16~18 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 18 | 120 | 73 | 52 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 18 | 143 | 110 | 86 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D-C | 18 | 95 | 57 | 47 | |||

| 18.1~20 | 3 | External cooling | Straight shank | d1*l3*d2*l1*3D | 20 | 130 | 79 | 55 | ||

| 5 | External cooling | Straight shank | d1*l3*d2*l1*5D | 20 | 153 | 101 | 77 | |||

| 8 | Internal cooling | Straight shank | d1*l3*d2*l1*8D-C | 20 | 110 | 74 | 62 | |||

| Applicable table of processed materials | 回 | very suitable | 回 | suitable | ||||||

| number | Processed materials | |||||||||

| Mild steel HB≤180 | Carbon and alloy steels | Pre hardened steel, hardened steel | stainless steel | cast iron | Ductile iron | aluminium alloy | heat-resisting alloy | |||

| ~40HRC | >50HRC | ~60HRC | ||||||||

| 回 | 回 | 回 | 回 | 回 | 回 | |||||

remarks

1. If the 3 or 5 times drill bit needs internal cooling, please make a note when ordering, followed by C;

2.The handle is straight by default. If you need other handle standards, please refer to our handle materials or drawings for confirmation;

3. The default top angle is 140 degrees. If other angles are required, please mark or refer to the drawing;

4. If the order parameters are inconsistent with our company’s, you can inform our customer service personnel, and we will be enthusiastic to provide you with drawings for confirmation;

5. The cutter is not coated by default. If coating is required, please inform your requirements or processed materials

Write your message here and send it to us