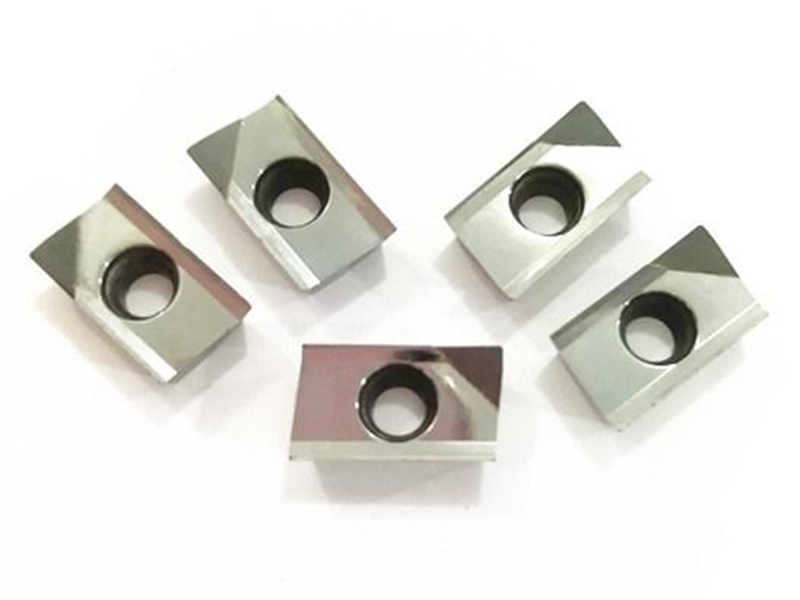

PCD Cutting Tool CNC Diamond Turning Milling Insert for aluminum

Choose a good full side PCD insert and get twice the result with half the effort

Use effect of OPT Full face PCD insert

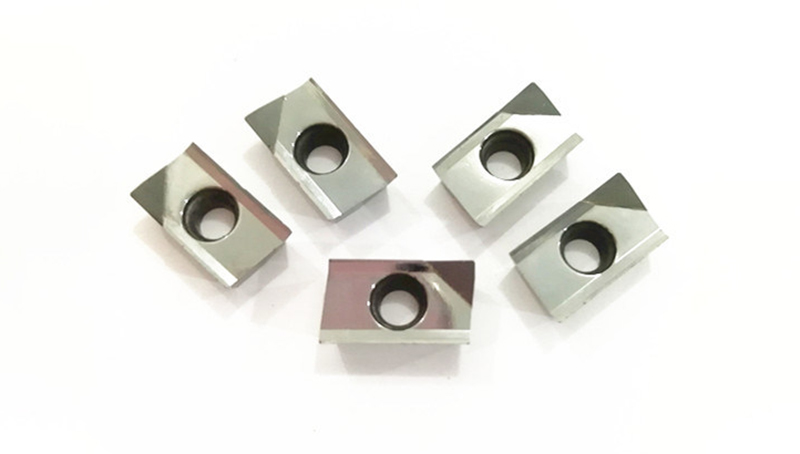

1. Low processing cost

2. Long service life

3. The turning and milling effect is bright

4. Long continuous processing time The OPT blade is processed continuously for 400 minutes, and the blade is normally worn without breakage

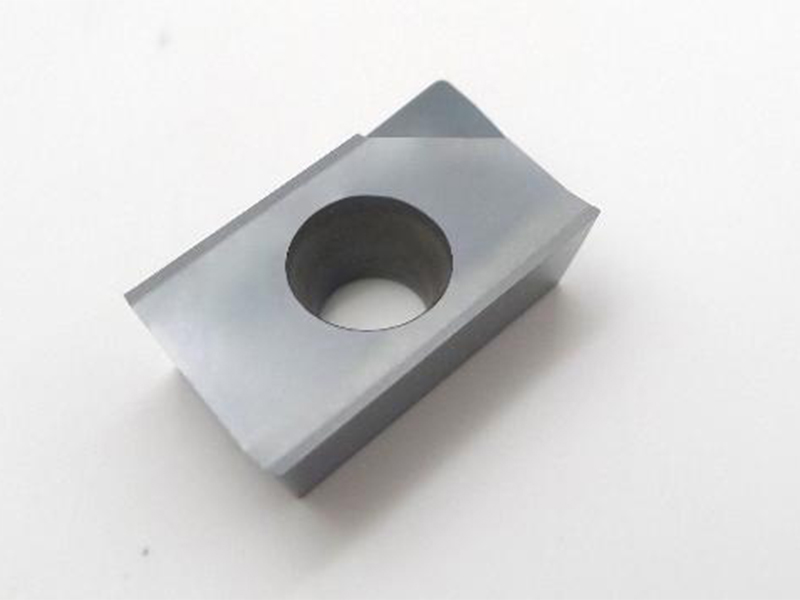

High cutting finish, support customization

Under the same cutting conditions, it can cut quickly without sticking the blade, with high efficiency and the desired finish.

The blade has high hardness, sharpness, good toughness and wear resistance. Various categories and specifications, supporting customized specifications.

High thermal conductivity, longer service life

The thermal diffusivity of diamond cutter is high, and its thermal conductivity is 1.5-9 times of that of cemented carbide and 2-6 times of that of copper. The heat generated by cutting is easy to dissipate, and the temperature of the cutting part of the tool is low. Longer service life.

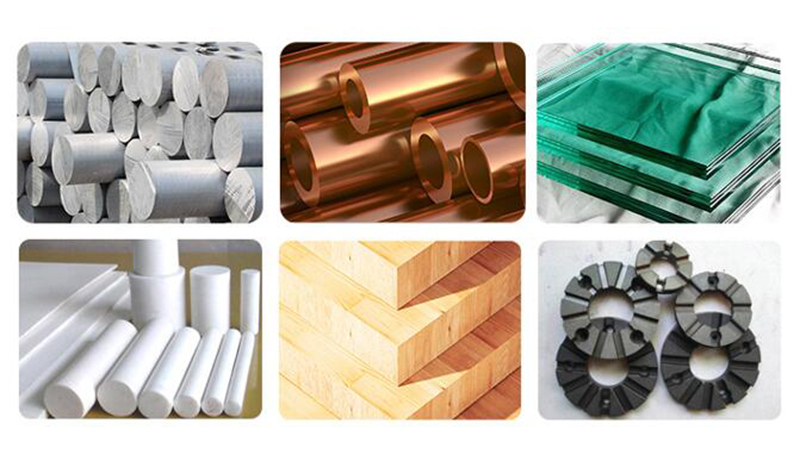

High speed processing, high production capacity

PCD diamond inserts are suitable for high-speed and dry machining. They are the choice of modern machining to improve efficiency. They can not only increase the daily output without any additional investment, but also use no cutting fluid. They are environmentally friendly and reliable.

|

Dimension, mm |

|||||

|

Series |

Model No. |

d |

S |

d1 |

R |

|

SNGN |

SNGN090304 |

9.525 |

3.18 |

- |

0.4 |

|

SNGN090308 |

9.525 |

3.18 |

- |

0.8 |

|

|

SNGN090312 |

9.525 |

3.18 |

- |

1.2 |

|

|

SNGN090316 |

9.525 |

3.18 |

- |

1.6 |

|

|

SNGN120308 |

12.7 |

3.18 |

- |

0.8 |

|

|

SNGN120312 |

12.7 |

3.18 |

- |

1.2 |

|

|

SNGN120408 |

12.7 |

4.76 |

- |

0.8 |

|

|

SNGN120412 |

12.7 |

4.76 |

- |

1.2 |

|

|

Series |

Model No. |

d |

Sl |

d1 |

R |

|

SNGA |

SNGA090304 |

9.525 |

3.18 |

3.81 |

0.4 |

|

SNGA090308 |

9.525 |

3.18 |

3.81 |

0.8 |

|

|

SNGA120404 |

12.7 |

4.76 |

5.16 |

0.4 |

|

|

SNGA120408 |

12.7 |

4.76 |

5.16 |

0.8 |

|

|

SNGA120412 |

12.7 |

4.76 |

5.16 |

1.2 |

|

|

Dimension, mm |

|||||

|

Series |

Model No. |

d |

S |

d1 |

R |

|

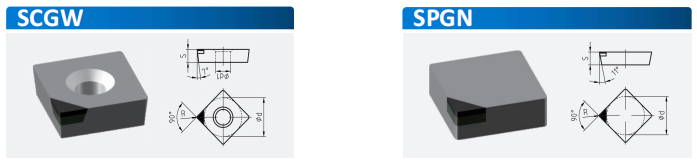

SCGW |

SCGW060202 |

6.35 |

2.38 |

2.2 |

0.2 |

|

SCGW060204 |

6.35 |

2.38 |

2.2 |

0.4 |

|

|

SCGW090304 |

9.525 |

3.18 |

4.4 |

0.4 |

|

|

SCGW090308 |

9.525 |

3.18 |

4.4 |

0.8 |

|

|

SCGW09T304 |

9.525 |

3.97 |

4.4 |

0.4 |

|

|

SCGW09T308 |

9.525 |

3.97 |

4.4 |

0.8 |

|

|

SCGW120404 |

12.7 |

4.76 |

5.5 |

0.4 |

|

|

SCGW120408 |

12.7 |

4.76 |

5.5 |

0.8 |

|

|

Series |

Model No. |

d |

S |

d1 |

R |

|

SPGN |

SPGN090304 |

9.525 |

3.18 |

- |

0.4 |

|

SPGN090308 |

9.525 |

3.18 |

- |

0.8 |

|

|

SPGN090312 |

9.525 |

3.18 |

- |

1.2 |

|

|

SPGN120304 |

12.7 |

3.18 |

- |

0.4 |

|

|

SPGN120308 |

12.7 |

3.18 |

- |

0.8 |

|

|

SPGN120312 |

12.7 |

3.18 |

- |

1.2 |

|

|

SPGN120316 |

12.7 |

3.18 |

- |

1.6 |

|

|

SPGN120408 |

12.7 |

4.76 |

- |

0.8 |

|

|

SPGN120412 |

12.7 |

4.76 |

- |

1.2 |

|