factory low price CNC Gun Bottoming Pipe Screw Straight Spiral Point Flute Machine Thread Carbide Tap

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for factory low price CNC Gun Bottoming Pipe Screw Straight Spiral Point Flute Machine Thread Carbide Tap, Welcome all nice buyers communicate details of solutions and ideas with us!!

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for , Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

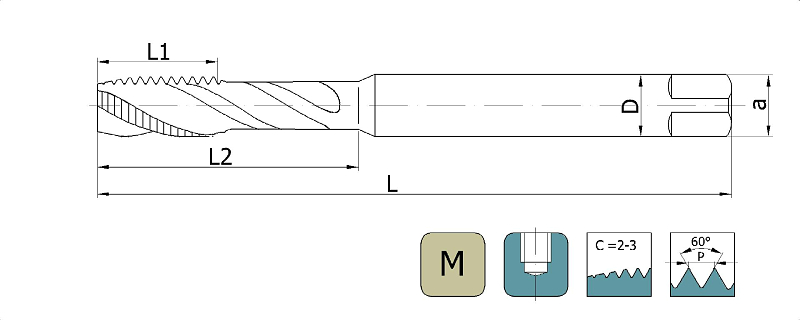

Customization

Customization a variety of specifications,

ISO metric thread, UN thread

Shank quare size according to customer requirements to meet different fixtures.

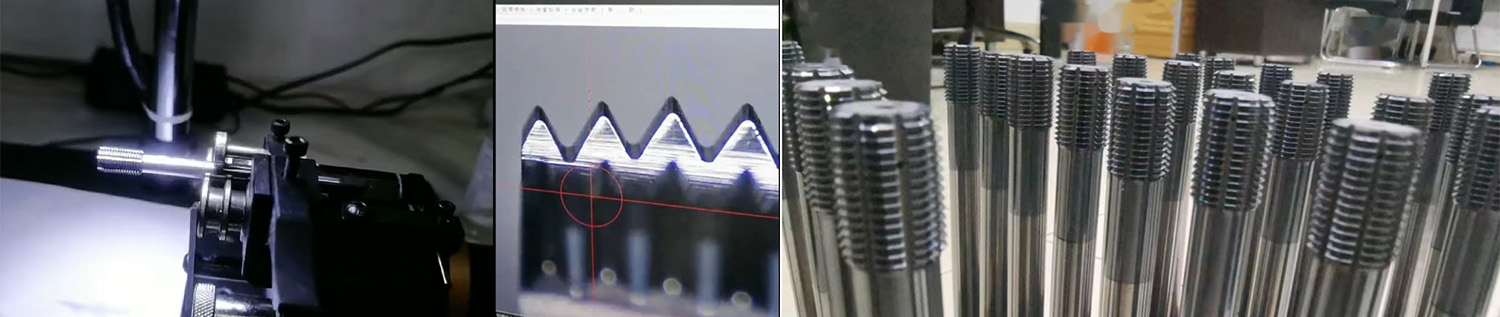

Quality control

Forming taps are 100% inspected, sure accurancy tolerance matches the size of go gauge and no go gauge.

Threading quality and qualification ensured.

Tool life

We use preimium cobalt materials to ensure the stability of products from raw materials

Match appropriate coating according to the workpiece materials. Thanks the high precesion thread grinding equipment to make sure stable quality for our products.

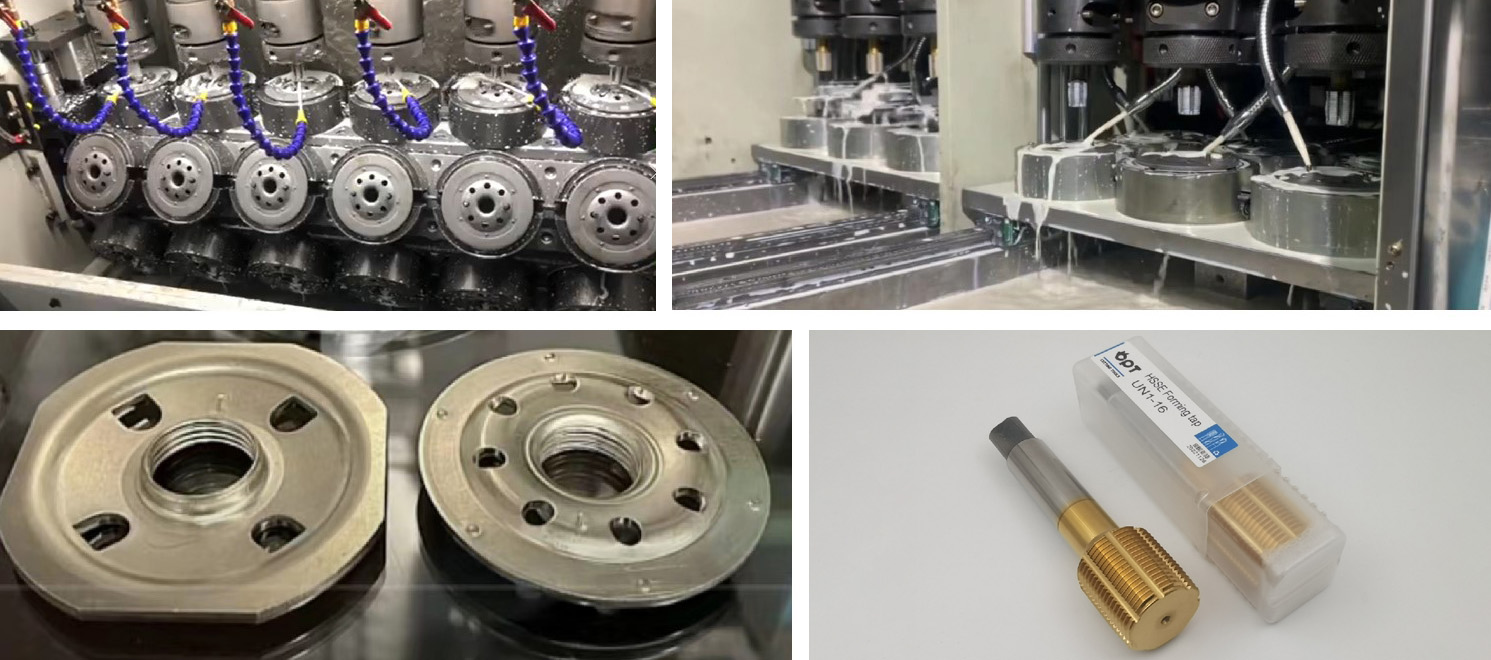

Forming tap for oil filter

We use preimium cobalt materials to ensure the stability of products from raw materials

Match appropriate coating according to the workpiece materials. Thanks the high precesion thread grinding equipment to make sure stable quality for our products.

Product production, inspection and display

Before ordering, please communicate with our pre-sales customer service:

1. Workpiece material

2. Whether product is surface treated after processing

3. Accuracy requirements, size of go gauge and no go gauge.Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for factory low price CNC Gun Bottoming Pipe Screw Straight Spiral Point Flute Machine Thread Carbide Tap, Welcome all nice buyers communicate details of solutions and ideas with us!!

factory low price Carbide Tap and Thread Tap, Our aim is to help customers realize their goals. We have been diligently working to create a mutually beneficial partnership and sincerely look forward to having you on board. In essence, when you choose us, you’re embracing a life of excellence.Welcome to visit our factory and welcome your order! For further inquiries, you should do not hesitate to contact us.

| ltemNo. | Product specifications | L1 | L2 | L | D | a | Z | Limit | Standard |

| SPS040070 | M4×0.7 | 13 | 21 | 63 | 4.5 | 3.4 | 3 | P2 | DIN |

| SPS050080 | M5×0.8 | 15 | 25 | 70 | 6 | 4.9 | 3 | P2 | DIN |

| SPS080100 | M8×1 | 16 | 35 | 90 | 8 | 6.2 | 3 | P3 | DIN |

| SPS080125 | M8×1.25 | 16 | 35 | 90 | 8 | 6.2 | 3 | P3 | DIN |

| SPS060100 | M6×1 | 17 | 30 | 80 | 6 | 4.9 | 3 | P2 | DIN |

| SPS070100 | M7×1 | 17 | 30 | 80 | 7 | 5.5 | 3 | P3 | DIN |

| SPS160125 | M16×1.25 | 18 | 18 | 110 | 12 | 9 | 3 | P3 | DIN |

| SPS100150 | M10×1.5 | 18 | 39 | 90 | 10 | 8 | 3 | P4 | DIN |

| SPS100125 | M10×1.25 | 18 | 39 | 90 | 10 | 8 | 3 | P3 | DIN |

| SPS120175 | M12×1.75 | 22 | 22 | 110 | 9 | 7 | 3 | P4 | DIN |

| SPS120150 | M12×1.5 | 22 | 22 | 110 | 9 | 7 | 3 | P4 | DIN |

| SPS120125 | M12×1.25 | 22 | 22 | 110 | 9 | 7 | 3 | P3 | DIN |

| SPS140150 | M14×1.5 | 22 | 22 | 110 | 11 | 9 | 3 | P4 | DIN |

| SPS140125 | M14×1.25 | 22 | 22 | 110 | 11 | 9 | 3 | P3 | DIN |

| SPS160150 | M16×1.5 | 22 | 22 | 110 | 12 | 9 | 3 | P4 | DIN |

| SPS180150 | M18×1.5 | 25 | 25 | 125 | 14 | 11 | 4 | P4 | DIN |

| SPS200150 | M20×1.5 | 25 | 25 | 140 | 16 | 12 | 4 | P4 | DIN |

| SPS220150 | M22×1.5 | 25 | 25 | 140 | 18 | 14.5 | 4 | P4 | DIN |

| SPS180200 | M18×2 | 26 | 26 | 125 | 14 | 11 | 4 | P5 | DIN |

| SPS140200 | M14×2 | 26 | 26 | 110 | 11 | 9 | 3 | P5 | DIN |

| SPS160200 | M16×2 | 27 | 27 | 110 | 12 | 9 | 3 | P5 | DIN |

| SPS200200 | M20×2 | 27 | 27 | 140 | 16 | 12 | 4 | P5 | DIN |

| SPS220200 | M22×2 | 27 | 27 | 140 | 18 | 14.5 | 4 | P5 | DIN |

| SPS240200 | M24×2 | 27 | 27 | 140 | 18 | 14.5 | 4 | P5 | DIN |

| SPS240150 | M24×1.5 | 27 | 27 | 140 | 18 | 14.5 | 4 | P4 | DIN |

| SPS180250 | M18×2.5 | 30 | 30 | 125 | 14 | 11 | 4 | P6 | DIN |

| SPS220250 | M22×2.5 | 32 | 32 | 140 | 18 | 14.5 | 4 | P6 | DIN |

| SPS200250 | M20×2.5 | 32 | 32 | 140 | 16 | 12 | 4 | P6 | DIN |

| SPS240300 | M24×3 | 34 | 34 | 140 | 18 | 14.5 | 4 | P6 | DIN |

| SPS270300 | M27×3 | 36 | 36 | 160 | 20 | 16 | 4 | P6 | DIN |

| SPS300350 | M30×3.5 | 40 | 40 | 180 | 22 | 18 | 4 | P7 | DIN |