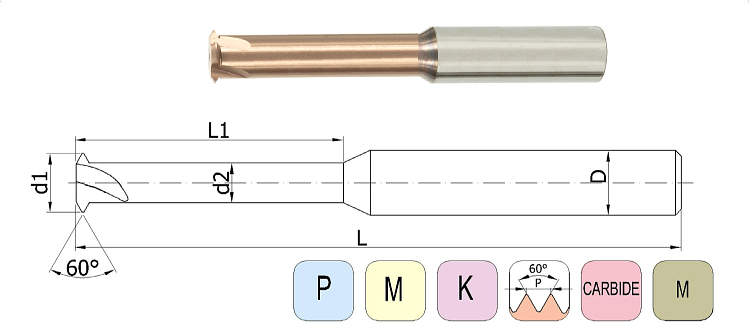

Tungsten Carbide alloy Single Tooth Spiral Milling Cutter CNC Tool

Single Tooth Range Tungsten Steel Thread

| LtemNo. | Specifications | d1 | d2 | L1 | L | D | Z | Standard |

| S0.25-0.35 1.053.5450D | 0.25-0.35 | 1.05 | 0.6 | 3.5 | 50 | 4 | 3 | ISO |

| S0.25-0.35 1.24450D | 0.25-0.35 | 1.2 | 0.75 | 4 | 50 | 4 | 3 | ISO |

| S0.3-0.5 1.556450D | 0.3-0.5 | 1.55 | 0.9 | 6 | 50 | 4 | 4 | ISO |

| S0.3-0.7 1.966.5450D | 0.3-0.7 | 1.96 | 1.1 | 6.5 | 50 | 4 | 4 | ISO |

| S0.3-0.8 2.358450D | 0.3-0.8 | 2.35 | 1.4 | 8 | 50 | 4 | 4 | ISO |

| S0.3-0.8 3.1510450D | 0.3-0.8 | 3.15 | 2 | 10 | 50 | 4 | 4 | ISO |

| S0.3-1.0 3.912450D | 0.3-1.0 | 3.9 | 2.5 | 12 | 50 | 4 | 4 | ISO |

| S0.5-1.5 4.815650D | 0.5-1.5 | 4.8 | 2.9 | 15 | 50 | 6 | 4 | ISO |

| S0.5-1.75 620650D | 0.5-1.75 | 6 | 4 | 20 | 50 | 6 | 4 | ISO |

| S0.5-2.5 7.725860D | 0.5-2.5 | 7.7 | 4.8 | 25 | 60 | 8 | 4 | ISO |

| S1.0-3.0 9.630L1075D | 1.0-3.0 | 9.6 | 6 | 30L | 75 | 10 | 2 | ISO |

| S1.0-3.5 10361075D | 1.0-3.5 | 10 | 6 | 36 | 75 | 10 | 2 | ISO |

| S1.0-4.0 12381275D | 1.0-4.0 | 12 | 7.3 | 38 | 75 | 12 | 3 | ISO |

| S1.5-4.0 144814100D | 1.5-4.0 | 14 | 9 | 48 | 100 | 14 | 3 | ISO |

| S2.0-5.0 165016100D | 2.0-5.0 | 16 | 10 | 50 | 100 | 16 | 3 | ISO |

| S0.5-0.8 3.916450D | P0.5-P0.8 | 3.9 | 2.8 | 16 | 50 | 4 | 4 | ISO |

| S0.5-1.0 4.8520660D | P0.5-P1.0 | 4.85 | 3.5 | 20 | 60 | 6 | 5 | ISO |

| S0.5-1.25 5.925660D | P0.5-P1.25 | 5.9 | 4.2 | 25 | 60 | 6 | 5 | ISO |

| S0.5-1.0 9.8351075D | P0.5-P1.0 | 9.8 | 8.5 | 35 | 75 | 10 | 6 | ISO |

| S1.0-1.5 7.932875D | P1.0-P1.5 | 7.9 | 5.8 | 32 | 75 | 8 | 6 | ISO |

| S1.0-1.75 9.9381075D | P1.0-P1.75 | 9.9 | 7.6 | 38 | 75 | 10 | 6 | ISO |

| S1.0-2.0 11.9401275D | P1.0-P2.0 | 11.9 | 9.6 | 40 | 75 | 12 | 6 | ISO |

| S2.0-3.0 144814100D | P2.0-P3.0 | 14 | 10.2 | 48 | 100 | 14 | 6 | ISO |

| S2.0-3.5 165016100D | P2.0-P3.5 | 16 | 11.5 | 50 | 100 | 16 | 6 | ISO |

Write your message here and send it to us