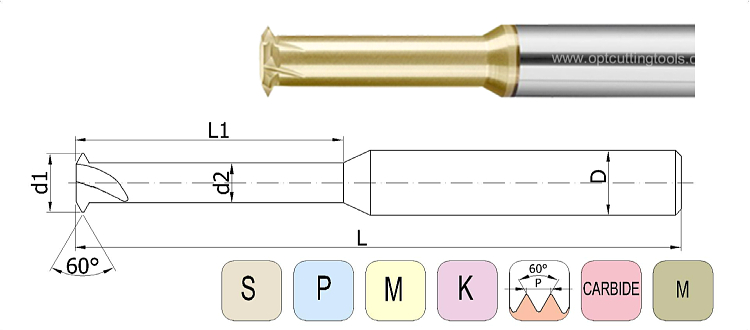

CNC thread cutter Carbide Single Tooth Cutter Thread Milling Cutter

Features:

It is suitable to process a few threaded workpieces of proofing pieces, many thread specifications and models, and it can also process American threads

Single buckle teeth have low processing resistance, strong universality, and convenient use Escape lengthening is particularly suitable for working conditions with complex types of deep holes and threads.

Advantage:

High efficiency side milling, dynamic processing, wear less than 1/2 compared with other companies' products.

Light knife side edge is good, side milling rough life is long, can reach the level of South Korea, Taiwan, Japan.

Europe and the United States, high-end brand tools.

Single Tooth Tungsten Steel Thread MillingCutter-Titanium Alloy/High Temperature Alloy

| LtemNo. | Specifications | d1 | d2 | L1 | L | D | Z |

| S0.35 1.24450X | M1.6*0.35 | 1.2 | 0.8 | 4 | 50 | 4 | 3 |

| S0.4 1.556450X | M2.0*0.4 | 1.55 | 0.9 | 6 | 50 | 4 | 3 |

| S0.45 1.966.5450X | M2.5*0.45 | 1.96 | 1.3 | 6.5 | 50 | 4 | 4 |

| S0.5 2.358450X | M3.0*0.5 | 2.35 | 1.6 | 8 | 50 | 4 | 4 |

| S0.7 3.1510450X | M4.0*0.7 | 3.15 | 2.1 | 10 | 50 | 4 | 4 |

| S0.8 3.912450X | M5.0*0.8 | 3.9 | 2.8 | 12 | 50 | 4 | 4 |

| S1.0 4.815650X | M6.0*1.0 | 4.8 | 3.4 | 15 | 50 | 6 | 4 |

| S1.25 620660X | M8.0*1.25 | 6 | 4.2 | 20 | 60 | 6 | 4 |

| S1.5 7.725860X | M10*1.5 | 7.7 | 5.6 | 25 | 60 | 8 | 4 |

| S1.75 9.630L1075X | M12*1.75 | 9.6 | 7.3 | 30L | 75 | 10 | 4 |

| S2.0 10361075X | M14*2.0 | 10 | 7.3 | 36 | 75 | 10 | 4 |

| S2.5 12381275X | M18*2.5 | 12 | 8.8 | 38 | 75 | 12 | 4 |

| S3.0 144814100X | M24*3.0 | 14 | 10.2 | 48 | 100 | 14 | 6 |

| S3.5 165016100X | M30*3.5 | 16 | 11.5 | 50 | 100 | 16 | 6 |

| S0.5-0.8 3.916450X | P0.5-P0.8 | 3.9 | 2.8 | 16 | 50 | 4 | 4 |

| S0.5-1.0 4.8520660X | P0.5-P1.0 | 4.85 | 3.5 | 20 | 60 | 6 | 5 |

| S0.5-1.25 5.925660X | P0.5-P1.25 | 5.9 | 4.2 | 25 | 60 | 6 | 5 |

| S0.5-1.0 9.8351075X | P0.5-P1.0 | 9.8 | 8.5 | 35 | 75 | 10 | 6 |

| S1.0-1.5 7.932875X | P1.0-P1.5 | 7.9 | 5.8 | 32 | 75 | 8 | 6 |

| S1.0-1.75 9.9381075X | P1.0-P1.75 | 9.9 | 7.6 | 38 | 75 | 10 | 6 |

| S1.0-2.0 11.9401275X | P1.0-P2.0 | 11.9 | 9.6 | 40 | 75 | 12 | 6 |

| S2.0-3.0 144814100X | P2.0-P3.0 | 14 | 10.2 | 48 | 100 | 14 | 6 |

| S2.0-3.5 165016100X | P2.0-P3.5 | 16 | 11.5 | 50 | 100 | 16 | 6 |

Write your message here and send it to us