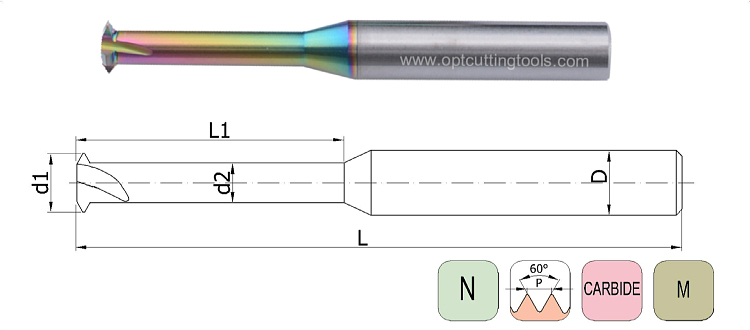

CNC 60 Degree Tungsten Steel Single tooth Thread Milling Cutter For Aluminum

Features:

The number of threaded holes for the suitable processing sample pieces is small, the thread specifications are many, the use is convenient, the single thread processing resistance is small, and the deeper threaded holes can be processed. The seven color DLC coating has the lowest friction coefficient and high resistance to fusion and corrosion of non-ferrous metals.

Advantage:

Nano coating,Give consideration to hardness and wear resistance.

Strictly select tungsten steel bars ,Hardened and firm,High hardness,Adopt high-quality fine tungsten steel bars,High rigidity and wear resistance, while improving the service life of the tool.

Single Tooth Dlc Seven Color

| LtemNo. | Specifications | d1 | d2 | L1 | L | D | Z | Standard |

| S0.25 0.723450DCL | P0.25 | 0.72 | 0.43 | 3 | 50 | 4 | 2 | ISO |

| S0.25 0.93.2450DCL | P0.25 | 0.9 | 0.63 | 3.2 | 50 | 4 | 2 | ISO |

| S0.3 1.054450DCL | P0.3 | 1.05 | 0.6 | 4 | 50 | 4 | 3 | ISO |

| S0.35 1.24450DCL | P0.35 | 1.2 | 0.75 | 4 | 50 | 4 | 3 | ISO |

| S0.4-0.5 1.556450DCL | P0.4-P0.5 | 1.55 | 0.9 | 6 | 50 | 4 | 3 | ISO |

| S0.45-0.6 1.966.5450DCL | P0.45-P0.6 | 1.96 | 1.1 | 6.5 | 50 | 4 | 4 | ISO |

| S0.5-0.7 2.358450DCL | P0.5-P0.7 | 2.35 | 1.4 | 8 | 50 | 4 | 4 | ISO |

| S0.5-1.0 3.1510450DCL | P0.5-P1.0 | 3.15 | 2 | 10 | 50 | 4 | 4 | ISO |

| S0.5-1.0 3.912450DCL | P0.5-P1.0 | 3.9 | 2.5 | 12 | 50 | 4 | 4 | ISO |

| S0.5-1.5 4.815650DCL | P0.5-P1.5 | 4.8 | 2.9 | 15 | 50 | 6 | 4 | ISO |

| S0.5-1.5 620650DCL | P0.5-P1.5 | 6 | 4 | 20 | 50 | 6 | 4 | ISO |

| S0.8-2.0 7.725860DCL | P0.8-P2.0 | 7.7 | 4.8 | 25 | 60 | 8 | 4 | ISO |

| S1.0-2.5 9.630L1075DCL | P1.0-P2.5 | 9.6 | 6 | 30L | 75 | 10 | 4 | ISO |

| S1.0-3.0 10361075DCL | P1.0-P3.0 | 10 | 6 | 36 | 75 | 10 | 4 | ISO |

| S1.25-3.5 12381275DCL | P1.25-3.5 | 12 | 7.3 | 38 | 75 | 12 | 4 | ISO |

| S1.5-3.5 12381276DCL | P1.5-3.5 | 14 | 9 | 48 | 100 | 14 | 4 | ISO |

| S2.0-4.0 12381277DCL | P2.0-4.0 | 16 | 10 | 50 | 100 | 16 | 4 | ISO |

Write your message here and send it to us